The working principle of the spring cone crusher is driven by a motor, and the linkage of gears makes the driveshaft and transmission gear drive the eccentric sleeve to rotate. The moving cone of the spring cone crusher makes a rotary motion under the action of the eccentric sleeve. The moving cone and fixed cone close or dissociate with each other, thus continuously impacting and crushing the material.

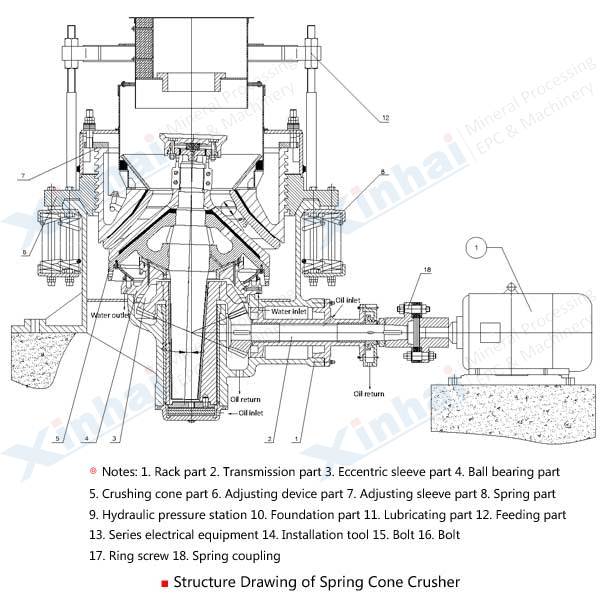

The structure of spring cone crusher is mainly composed of frame, fixed cone, moving cone assembly, spring mechanism, bowl shaft frame and transmission.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE