Recently we receipted a question from clients. The client’s linear vibrating screen in mineral processing plant occurred a scene that the materials on screen obviously hard conveying, and then materials output from one-side, the problem can’t be solved in a moment. So the client came to us for help. Then the relative technics arrived the scene in processing plant, researching the problem from the vibrating screen, and analyzing all the aspects causing these problems one by one.

Actually, this is an old problem for linear vibrating screen. The technics check the vibrating screen from technical parameters after arriving the processing plant.

Use the table of contents below to navigate through the guide:

01The tilt angle of vibration motor

In brief, the vibration source of linear vibrating screen is vibration motor. The materials on the screen can be upsprung and moved by an exciting force of a certain magnitude in a fixed direction.

The tilt angle of linear vibrating screen is a certain value. Some vibrating screen can adjusted while some can’t be adjusted. Commonly adjusting the direction of exciting force is the solution under this circumstance. The angle of eccentric block is adjusted to change the force according to the material condition and capacity.

02The strength and damage of damping spring

The importance of damping spring is no less than vibration motor for linear vibrating screen. It is important in maintain the stability and increasing the working life of vibrating screen.

Damping spring can be divided into rubber spring, steel spiral spring, and composite spring. The damping spring thickness is different, the strength is different for steel spiral spring. If the vibrating screen is too large or the vibration force from vibration motor is too strong, a thin damping spring can lead to be broken and even influencing the operation of vibrating screen, causing the material wandering.

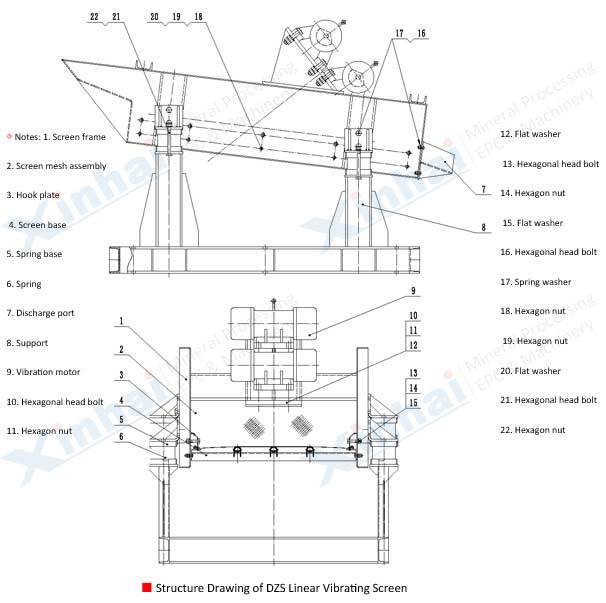

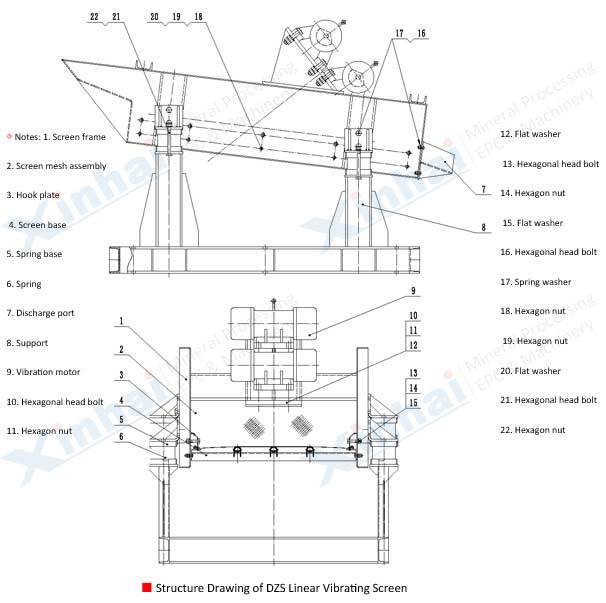

The Structure of Linear Vibrating Screen

03The center of vibrating screen gravity and the deposit of eccentric block

Commonly, these technology problems, such as the center of vibrating screen gravity and deposit of eccentric block, won’t appear in linear vibrating screen from formal mineral processing equipment manufacturer. After examining, technics assured the center of vibrating screen gravity was stable and the deposit of eccentric block was balanced.

04The screen box is out of shape

The screen box is the part above the vibration motor and under feeding nose, which is made up of screen reel and fixed screens. The screen reel need to bear the gravity of screened material and the strong exciting force of vibration motor at the same time. If the strength of the screen reel is not enough, the screen reel is easy to be out of shape and even broken.

Besides, expect the material of screen reel, it still need unique welding technology and a stable design. The screen part of linear vibrating screen from this client is welded by rolled steel, and part of it is connected with high-strength bolt. The whole part of it is good in stiffness and strength, secure and reliable.

Through a series checks of technical parameters, technics found that the vibrating screen in this mineral processing plant didn’t have any problem. So technology fault was executed. Technics knew from talking with clients that the operating personnel was not professional enough, sometimes even didn’t operate strictly according to the operating instructions. It causes the feeding coming and going, largely influencing the screen efficiency, and causes the material to bear the force the deviation to be big, thus causes the material to run off, therefore the material must be uniform continuously.

After listening to the analysis of technical experts, customers quickly adjust the feeding to maintain even feeding. After observation for a period of time, the linear vibrating screen has returned to normal, and there is no problem of discharging deviation.

In addition, technical experts also suggest that, in addition to the above technical parameters and operational aspects, the periodic maintenance of vibration screen is also very important. As the saying goes, one move makes a difference. If a part of the aging loose problem, it is likely to lead to the linear vibrating screen the whole screen surface uneven, the sieve body instability, resulting in off-track discharge, serious even abnormal noise, serious wear and other problems. Therefore, it is necessary to carry out regular inspection and maintenance of the equipment.

To sum up, the operation of linear vibrating screen is related to many aspects, including the technical parameters of the equipment, whether the operation is standard and regular maintenance. Vibration screen technical experts suggest: first, please buy equipment from the regular mineral processing equipment manufacturers, to ensure the quality of equipment; In addition, in daily production, operating experts should be familiar with the working principle, performance and common fault phenomenon of the vibration screen, do daily maintenance, in order to reduce the failure rate, improve work efficiency. When there is a problem of poor material delivery, material deviation, we can according to the above four points one by one to eliminate, find the corresponding solution.

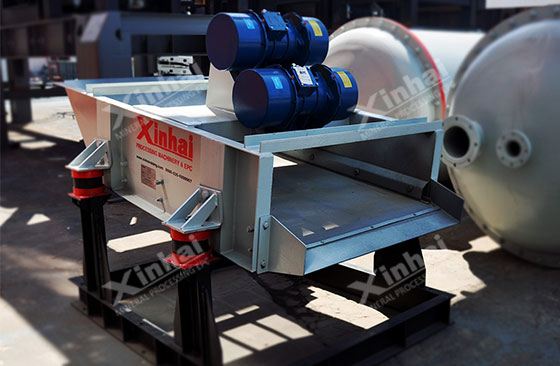

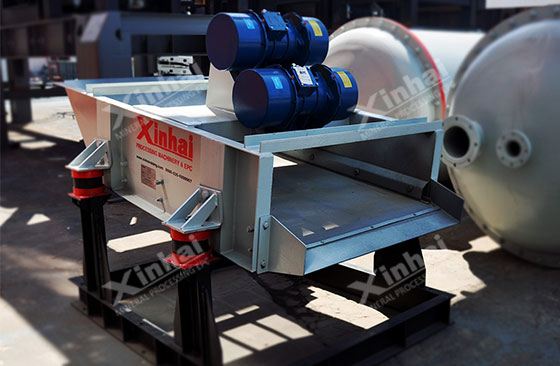

05Xinhai Vibrating Screens

Circular Vibrating Screen

Auto centering Vibrating Screen

Linear Vibrating Screen

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE