With the decrease of the grade of raw ore, the requirement for the technical level of gold separation is increasing day by day. In recent years, new gold separation methods and new gold separation equipment have been developed and put into the gold ore dressing, which has improved the index of gold separation.

Xinhai has long been committed to the development and innovation of gold separation technology and equipment, who can provide the reliable gold separation equipment and process to each gold miner. Here are several common gold separation methods.

Use the table of contents below to navigate through the guide:

01Single flotation process used in gold separation

Single flotation process is used to separate coarse and middle gold ore.

The gold ore is crushed and ground to the pointed particle size. With the grinding equipment, the gold ore is fed to the flotation cell with the sodium carbonate as a modifier and the butyl xanthate and butylamine aerofloat as a collector for separating the useful minerals and gangue minerals by the different hydrophobic of the mineral surface.

02Flotation with Hg used in gold separation

Flotation with HG process is used to separate natural gold minerals with coarse particle size and associating with pyrite and other sulfide ore.

Compared with single flotation process, the slurry is added the Hg after the grinding stage in this flotation process. This method is called adding Hg in the ball mill that is to say while grinding the minerals, the Hg will be added to extract the gold.

Another method is adding the Hg outside the ball mill to extract the gold. The Hg spreads in the gold particles to form the solid solution finally. When heating the solid mercury, the sponge gold will be got.

03Gravity separation process used in gold separation

Because of the large proportion of gold, gravity separation process is the most common method of recovering gold, and is often used in combination with other gold separation methods to treat all kinds of gold ores, especially the alluvial gold mine. Gravity separation process mainly uses the different gravity of gold and other minerals to achieve the gold separation. The bigger difference of the minerals is, the easier of the separation will be. Usually, after the vibrating screen, jig and concentrating table, the gold -bearing ore will become the gold concentrate.

04CIP process (carbon in pump) used in gold separation

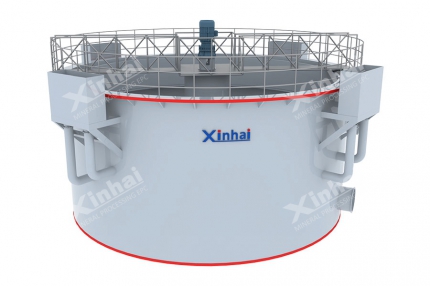

The ore is ground to a certain particle size and then it will be leached. When leaching, the activated carbon will be added to the leaching tankto improve the leaching rate of the gold. Finally, the gold-bearing carbon will be obtained by this gold separation process. Using high temperature to remove the gold in the carbon. Then the electrolysis method will be used to purify the gold during which some measure will be taken to recycle the tailing and the gold in the leaching liquid.

05Microbial leaching process used in gold separation

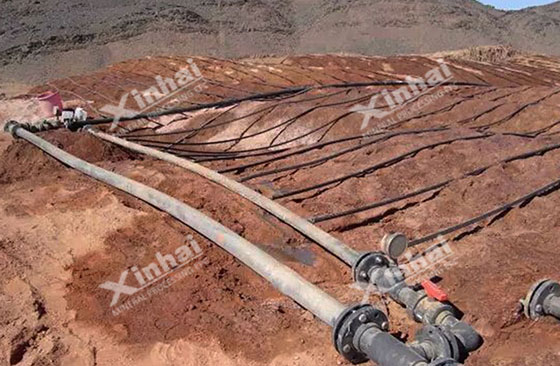

Microbial leaching process is usually used in the ore with low quality of gold and in the mine with large stone capacity. The sulfur mine such as iron sulfide in the ore wraps the gold which prevents the reaction between the cyanide leaching and gold ore. Before leaching, the microorganism, such as ferrooxidans, will be used to resolve the sulfur mine in the surface of the gold. At the same time, the cyanide in the bacterial liquid reacts with the gold making it enter into the leaching liquid. Then the gold in the leaching liquid will be recovered.

In the actual production, we often need to determine the best gold separation process according to mineral processing test, gravity separation, gold cyanidation or flotation process, a combined process.

At present, under the stimulation of increasing demand and high gold price, the promotion and application of new gold separation equipment and processes will continue to be extended.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE