As one of the important mineral processing equipment, the flotation cell often meets the phenomenon of unstable foam in the tank, such as too much and too big foam, too less and too small foam.

So, what is the reason for these problems?

Firstly, we should learn about the generation of foam in the tank.

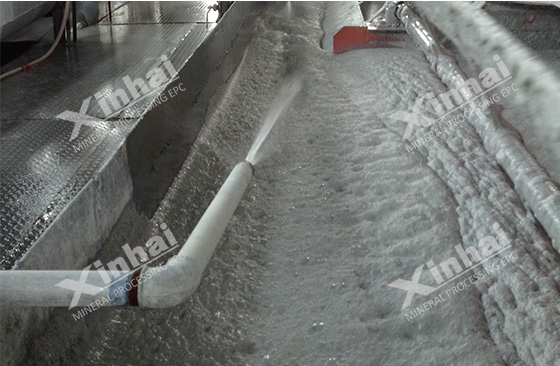

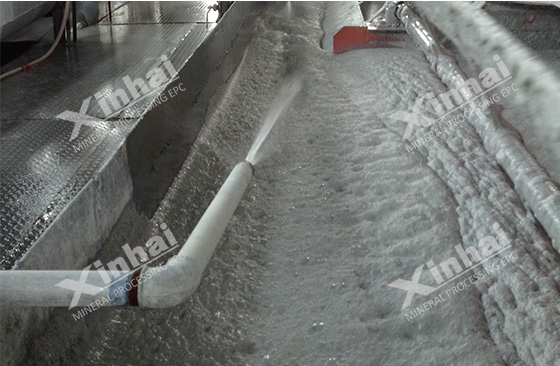

The foam is created by injecting low-pressure air with an external tool, just as the bubble produced by inflating water with the pipe.

However, the foam produced by air inflation is not stable, and the quantity is uncertain. Therefore, using the foaming agent can increase the foam quantity and guarantee the stability of the foam.

So, what is the main reason for causing too much or too less foam in the flotation cell? That's the foaming agent. In general, the excess dosage of foaming agent will cause too much and too large foam in the flotation tank, and even sometimes, the foam is too large to reflect light on the surface. On the contrary, the insufficient use of the foaming agent will cause too less and too small foam.

Then again, what is the effect of too much or too less foam on the flotation operation? If the foam is too large or too small, the amount of impurities will be too less, which cannot achieve the expected flotation efficiency. It not only affects the flotation effect, but also influence the final recovery rate.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE