Xinhai automatic flotation control system can be applied to metal mines, nonferrous metal mines and nonmetallic minerals. It mainly contains pulp density, the amount of reagent, the liquid level of flotation tank and inflating volume. Finally, it can enhance the concentrate grade and recovery, stabilize the flotation process, and reduce the costs in the dosage of reagent and labor personnel.

This automatic control system determines the pulp density and flow through real-time detection. And with the operation of PID, it can adjust and dilute water flow in order to make the pulp density stable in a set point. The liquid level is controlled by the close loop pulp level inverse system controlling the amount of flotation froth. Thus, it can avoid destroying the motor and mechanical device.

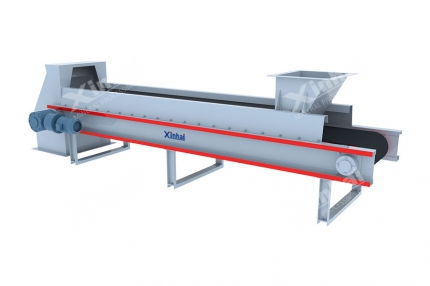

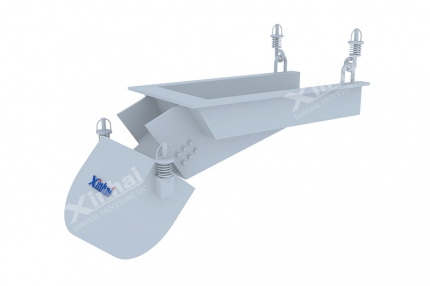

The amount of reagent is controlled with Xinhai NC dosing machine. CNC dosing machine is conducive to the management of mineral processing technology and the adjustment of technical indicators. This kind of machine is stable, economical and practical. It can be widely used for ferrous metals, nonferrous metals, noble metals and nonmetallic minerals. In addition, it can effectively guarantee the high recovery.

It can be divided into two stages: the first is to calculate to make sure the dosage of reagent; the second is to optimize and control the flotation index.

Besides, the preparation liquid is injecting into the high medicine chest 1. Then the liquid flows into the low kits 6 because of level difference. Valve 4 control pharmaceutical liquid height remains constant in low kits 6. The liquid volume outflow from 6 and 7 control valve depends on the valve opening and the control valve opening time, the opening time of the control valve is controlled automatically by the host, therefore, the control of liquid flow is achieved. It has rational structure: the medicine chest, liquid constant devices and all kinds of valves are made of stainless steel with good corrosion resistance ability.

Moreover, this system is also equipped with an on-line grade monitoring module which can analyze the concentrate grade and transmit the information to the PLC.

Xinhai automatic flotation control system effectively improves the operating conditions and environmental protection. With years' efforts of elites, Xinhai can provide you with the excellent technologies and service. And it advocates "quality, performance, price, working period and service, the five-star service" and "one-stop service", which has become the model in the industry. The company develops with each passing day. Demand of the products exceeds the supply.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE