Compared with other countries in the world, Chinese economic growth rate has been enviable. But the updated data in China shows a significant drop in speed, which caused a big problem for other countries. Under the effect of the Chinese economic slowdown, what impacts on earth have affect the overseas mining equipment manufactures?

Siemens, BASF, United Technologies and Hitachi, Ltd. showed that the impact of Chinese economic slowdown has brought a great influence on them.

The situation of Siemens is becoming more terrible due to less large orders in China. Hitachi showed its first-quarter sales of construction equipment in China fell more than 40%, and this trend would get rebound till January in the next year at least. Caterpillar has reduced production in China and the Joint Technology company also lowered its estimate of subsidiary sales, which mainly caused by the weak demand from China.

However, problems are often accompanied with forceful tackles and changes of national policy. Some measures means that China will change some of the existing development policies. For instance, the Government will promote the high-ranking development of the network value chain in the industrial structure, so that to get rid of the status of China as a low value-added producer.

Whether affected by the pressure of Chinese economic slowdown or the challenges from Chinese policy shift, mining machinery industry should take this as an opportunity. Companies should set the high-ranking development of industrial structure as the basic requirement; improve technology innovation and equipment production to avoid traditional, aging, backward production, So as to avoid increasing burden in their own development and progress of national industry.

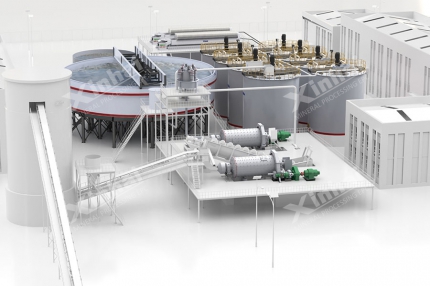

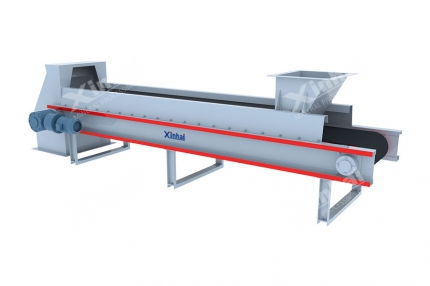

Yantai Xinhai Mining Machinery Co,.Ltd. regards innovation as a cornerstone to exceed other companies. Xinhai mineral processing EPC provides one-stop services for the mine owners. We always takes high-ranking technology, equipment and services to meet challenges and make achievements. For example, dry tailings discharge technology has provide a good solution to deal with the problem of mining tailings and its market is becoming larger and larger. With unique wear-resisting rubber applying in all kinds of mining equipment to improve our wear-resisting performance, slurry pumps, cyclones, and other products are exceed supply. We believe that only remaining at the forefront of technological innovation can the company ranks in the forefront of the social economy.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE