China is the largest iron ore production and consumption power in the world, but the domestic iron ore is featured with "lean, fine, mixed", which urges Chinese people to make a lot of research on the iron ore dressing process. In recent years, China has already become the center of iron ore research and development in the world, whose technology has reached the international advanced level. It is known that hematite is the main raw material of the iron industry, its recycling has become the research focus. Here is the newest hematite processing technology—the magnetic separation-anionic reverse flotation process.

Firstly, magnetic separation process separates valuable minerals, at the same time, hematite is usually associated with sulphur and phosphorus, and these harmful impurities can be removed by anionic reverse flotation process. Besides, many new types of equipment are introduced in the latest hematite ore dressing process. For example, magnetic separation column, SLON vertical ring high gradient magnetic separator and vibration pulsedmagnetic separatorare widely applied in magnetic separation process, especially SLON vertical ring high gradient magnetic separator is the most advanced magnetic separation equipment currently, it not only deals with the blockage of permeability medium in horizontal ring magnetic separator, but also realizes high recovery rate and high grade of hematite concentrate. As to anionic reverse flotation process, many mineral processing plants adopt flotation column to replace flotation cell, which increases the recovery rate of hematite and the grade of iron concentrate.

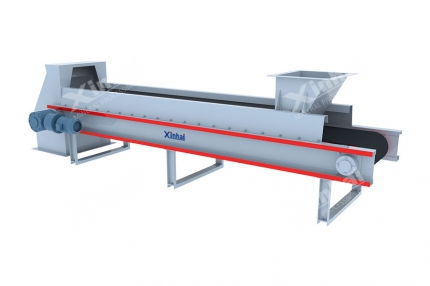

As the ore property constantly goes complex, the research on the latest hematite processing technology is deeper. Xinhai can not only design the ore processing technology according to the customers' needs, but also provide the mineral processing equipment.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE