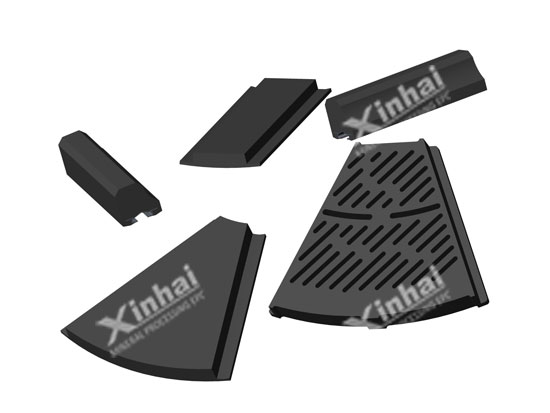

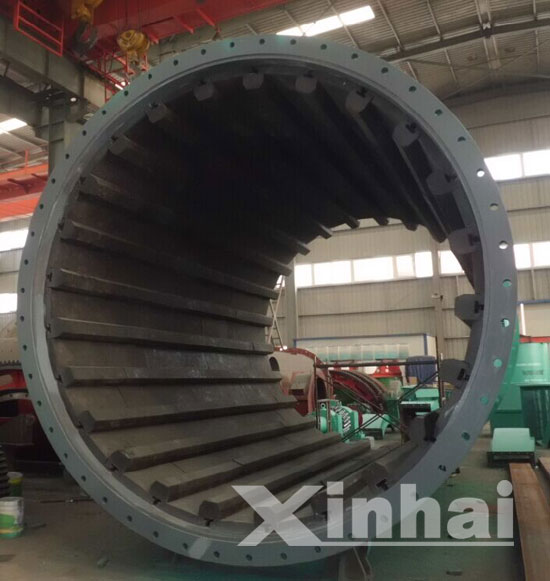

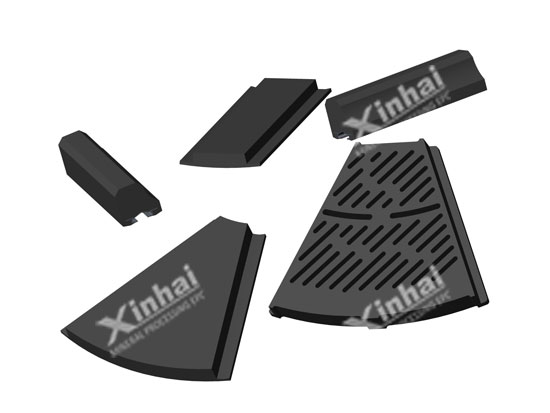

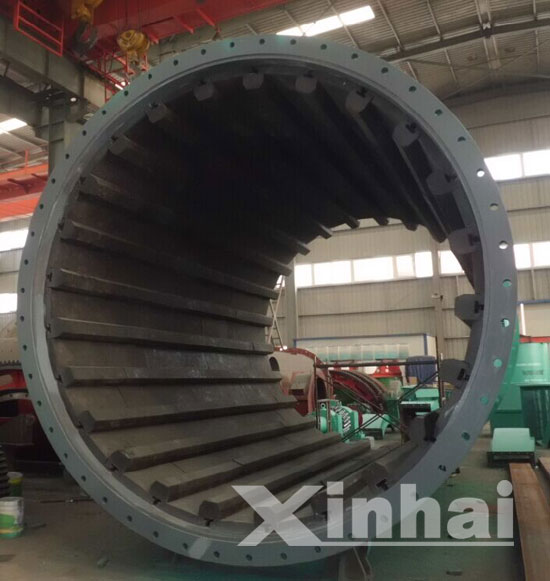

Nowadays, ball mill is widely applied in mineral processing, metallurgy, chemical industry, construction and other fields, so the quality of ball mill has aroused our attention. In fact, liner plays a dominant role in the quality of ball mill, its main role is to prevent cylinder from wearing, so it is also one of the most wearing accessories. Xinhai will explain some reasons for liner wear and provide some improvement measures according to many years of mineral processing experience.

Reasons:

Liner plays a protective role in ball mill, which can reduce the frequency of cylinder friction and effectively avoid the damage to parts from materials. However, what can cause the liner wearing of ball mill?

Firstly, wrong installation method can lead to uneven liner stress, then lead to liner fracture.

Secondly, in the process of ball mill manufacturing, the selected lining uses poor material quality, the service life is much is shorter, and the wear resistance is poor, so liner is easier to cause wear problem.

Last, unreasonable liner structure can cause uneven wear degree in different parts. The thinner liner is easier to wear.

Improvement Measures:

1. Select reasonable steel ball and liner. Xinhai controls the hardness of ball mill liner and steel ball within a reasonable range. Besides, reasonable steel ball diameter can prevent friction between liner and steel ball.

2. Please pay attention to the selection of liner material. Xinhai often chooses better wear resistant material to improve the wear resistance of liner.

3, Xinhai often chooses low hardness of steel ball for recently replaced ball mill liner. After running 1 to 2 months later, the hardness of liner can be increased. Then Xinhai will select relatively high hardness of steel ball, which can greatly improve the service life of liner.

4, Strict quality assurance. Please exchange the liner if the liner cannot match with steel ball. Then Start debugging to guarantee bolt-up and ensure the normal operation of liner.

The liner has a vital influence on the performance of ball mill. In order to avoid unnecessary influence on production, the plant must select high-quality ball mill equipment. As a professional ball mill manufacturer, Xinhai committees to provide the best ball mill equipment by relying on its high - end technology, rich experience and first-class service level.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE

.jpg)