02/

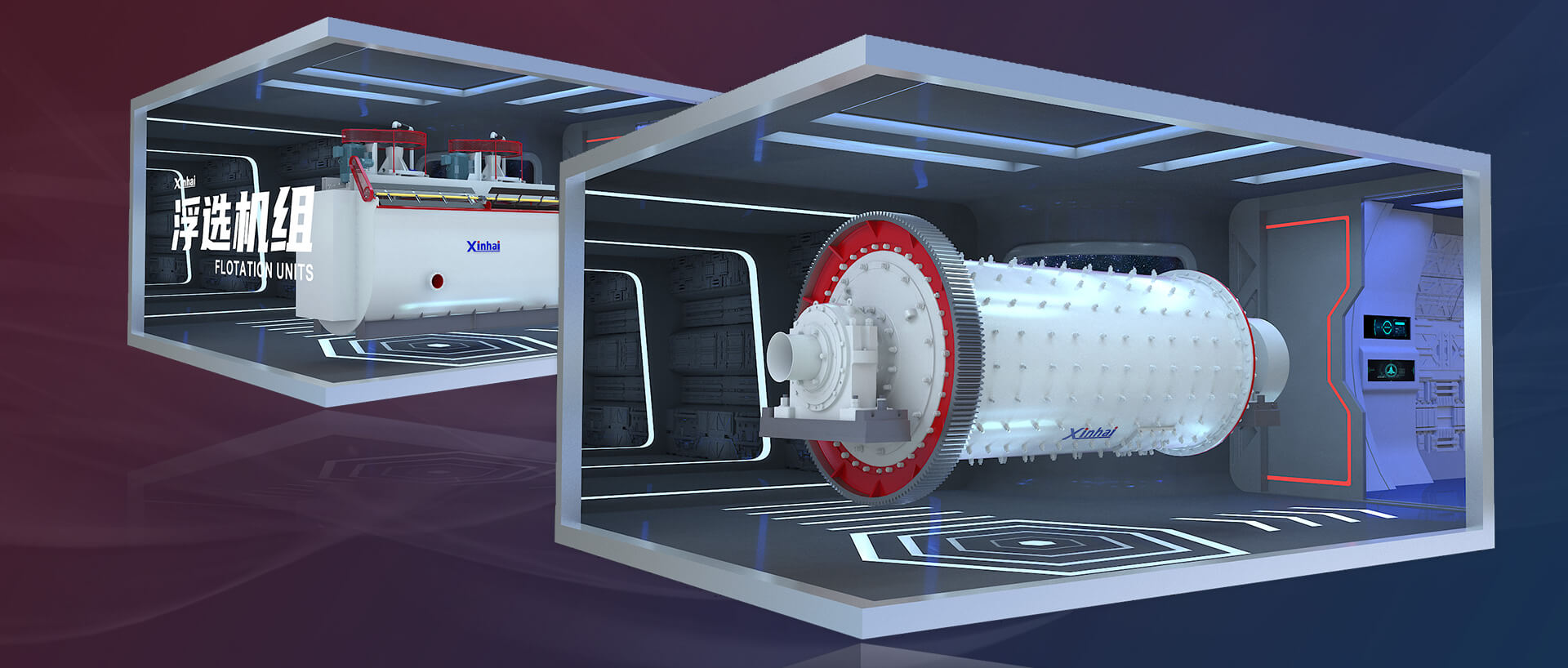

Design of green & intelligent concentrator- High standard intelligent design

Collect, monitor and analyze all production online data,

the data utilization rate is 100%

Automatic crushing/grinding/pumping station, centralized control+ intelligent inspection

The concentrator personnel are reduced by 20%

Guarantee the premise of production index,

2%-4% of the processing capacity when raising the grinding table

The management efficiency is improved by 20%

through intelligent analysis and sorting of production

and operation data, information push.

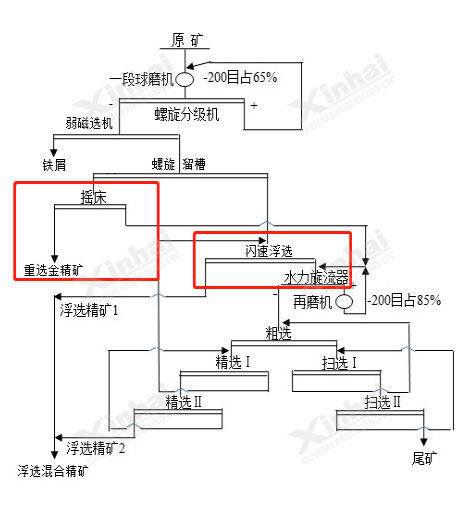

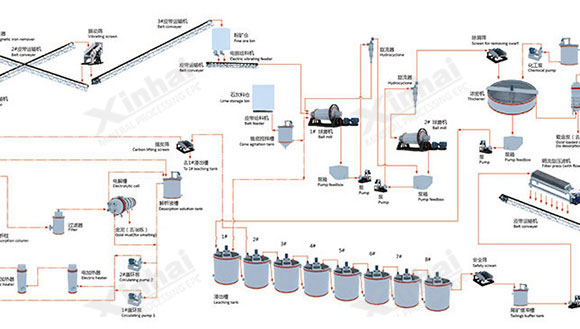

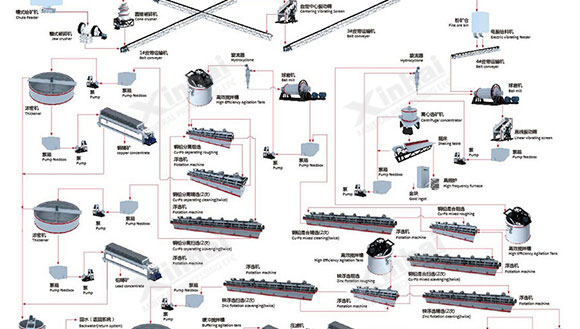

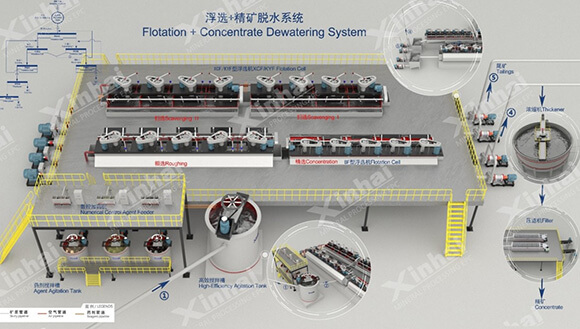

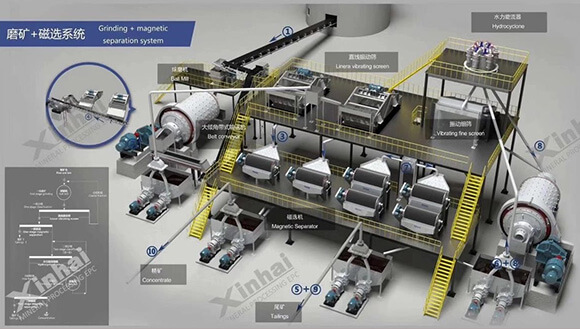

Flotation + magnetic separation on copper-bearing iron mineral

A large-scale iron mine in South America contains a certain amount of copper. One large-scale enterprise adopted a traditional process — crushing on site, dry separation for discarding non-magnetic ores. A large number of non-magnetic copper are discharged, the rest of copper is treated by flotation as the borderline sulfide.

Innovation points

-

01

There were recyclable non-magnetic copper minerals in iron ores, therefore, traditional process of dry separation for discarding non-magnetic ores was not adopted.

-

02

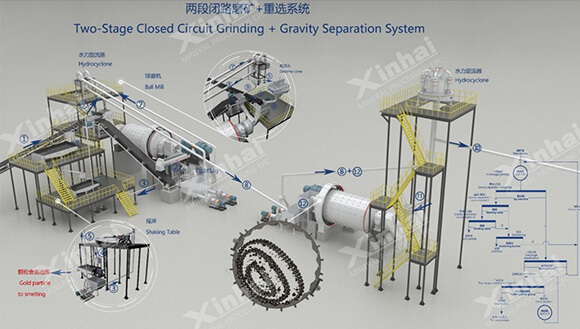

Due to the fragility of copper minerals, one stage of grinding and two stages of classifying were adopted. Enlarging the discharging particle size of ball mill and adding one stage of flash flotation in grinding and classifying circuit were to ease the argillization; adding one stage of flash flotation before roughing in flotation process was to separate the copper minerals with fragile foams as fast.

-

03

One stage of scavenging was added after concentration I to prevent concentration tailings from flowing into the iron products, so as to obtain sulfur concentrates. This process was rarely used before.

Equipment Innovation

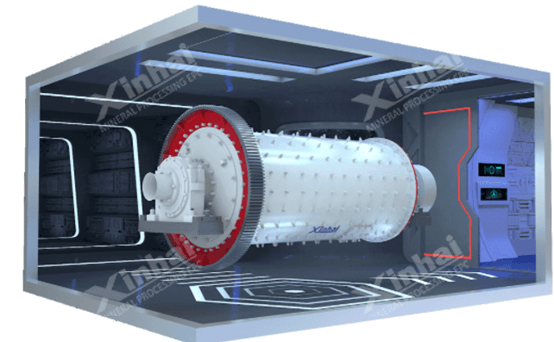

In terms of equipment technological innovation, Xinhai has upgraded more than 80% of mining equipment.

Taking the ball mill as an example, Xinhai can customize all aspects of ball mill equipment according to customer's requirements, including *transmission system, jack up device, feeding device, gear and pinion set & spray lubrication system, rolling bearing, overall rack and etc.,* which help customers achieve energy saving, low consumption, high efficiency.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080