Why Choose Xinhai?

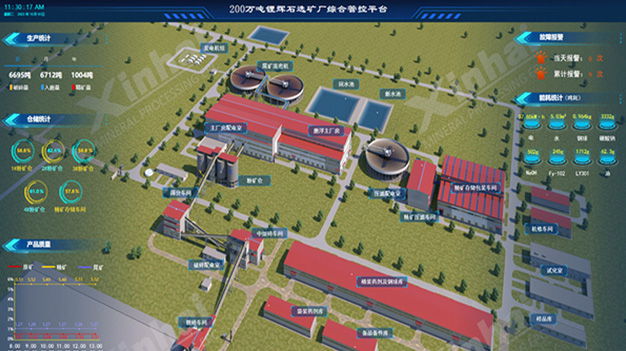

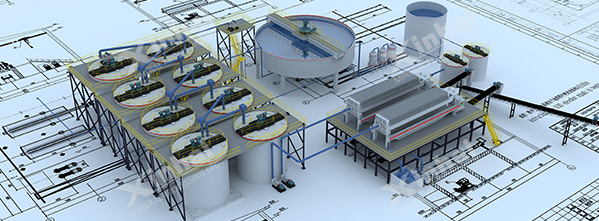

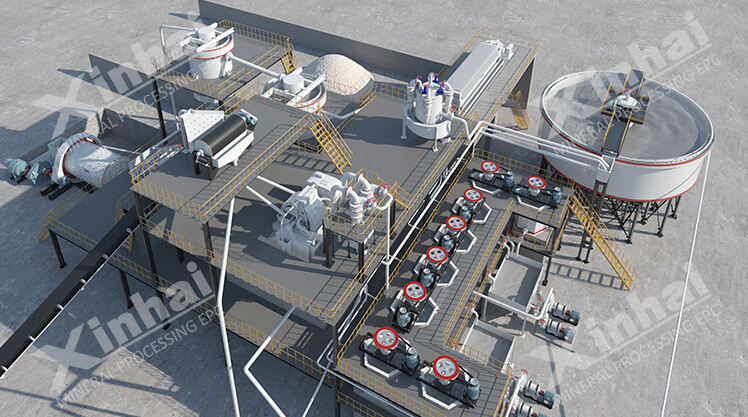

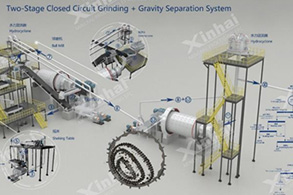

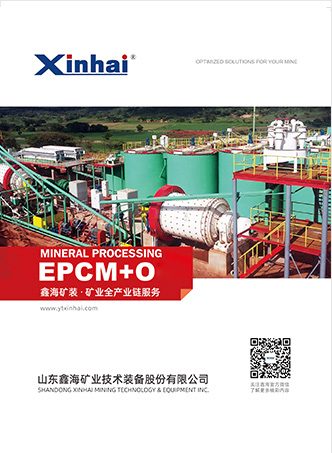

As a proposer and practitioner in mine EPC+M+O service, Xinhai has served nearly 2,000 mines and completed over 500 EPC+M+O projects in more than 100 countries and regions around the world. Xinhai installation and commissioning department has carried out installation and commissioning work at home and abroad all year round. It has more than ten years of practical experience and establishes a scientific and efficient assessment system so that each EPC+M+O project can be completed according to standardization, process and intelligence.

01

Rich experience in domestic and foreign projects

02

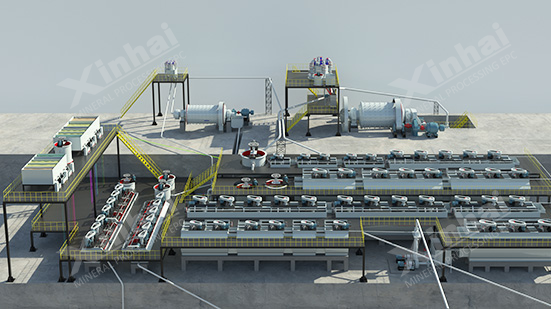

Complete service teams for various chains

Shandong Xinhai Mining Technology & Equipment Inc. has assembled a complete service team for various chains, focusing on providing one-stop, professional, intelligent and systematic mine EPC+M+O service. With the collaborative cooperation of professional subsidiary teams, we provide strong support for all aspects of EPC+M+O services.

SHANDONG XINHAI MINING TECHNOLOGY & EQUIPMENT INC.

Mineral Processing EPC+M+O Service

-

e

BEIJING XINHAI E-COMMERCE CO., LTD.

-

YANTAI XINHAI MINING RESEARCH & DESIGN CO., LTD.

E

-

P

YANTAI XINHAI INTELLIGENT EQUIPMENT CO., LTD.

YANTAI XINHAI AUTOMATION TECHNOLOGY CO., LTD.

YANTAI XINHAI MATERIALS TECHNOLOGY CO., LTD.

-

YUNNAN XINHAI CONSTRUCTION ENGINEERING CO., LTD.

C

-

M+O

YANTAI XINHAI PROJECT MANAGEMENT GROUP CO., LTD.

HONGKONG XINHAI MINING SERVICES LIMITED

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

Engineering Consulting

Engineering Consulting