Mine Research Institute

Xinhai Mine Research Institute is composed of a laboratory, experimental laboratory, and solution commissioning department. With over 20 years of in-depth practice, Xinhai has accumulated solid professional knowledge and rich practical experience. The institute has obtained CNAS international certification and has a first-class industrial-grade pilot testing base. It successfully completes 180 experimental research projects annually, and its experimental capabilities have reached an international advanced level.

01

Tailoring Technical Solutions for Each Mine with Innovative Thinking

Xinhai Mine Research Institute adheres to an innovative concept, tailoring customized technical solutions for each mine. Before starting a research project, comprehensive preliminary discussions are conducted to ensure the plan's effectiveness. Innovative thinking is adopted to formulate experimental plans for each ore sample, fully considering and utilizing its unique mineral characteristics. For gold mineral processing alone, there are 29 innovative process technology solutions.

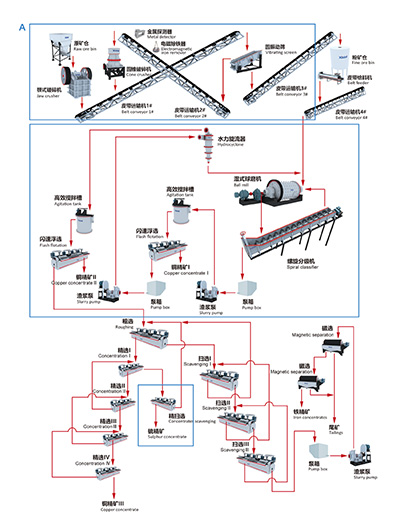

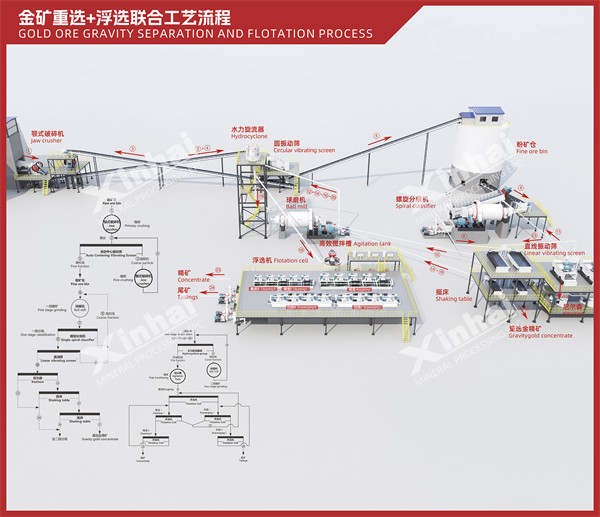

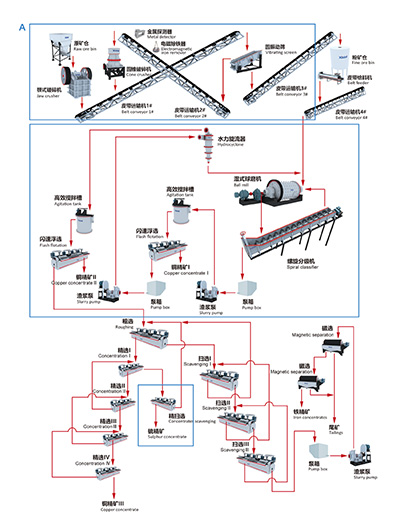

Flotation + Magnetic Separation Process Flowsheet for a Copper-Iron Ore in Peru

A large iron ore in Peru contains 0.4% to 0.7% chalcopyrite, and the copper minerals are very brittle and easily break into powder, with the foam easily breaking during flotation. A large iron ore company used the traditional iron ore development approach, crushing and dry selecting on-site at the mining site, resulting in many copper minerals being lost as they are brittle, easily broken into powder, and non-magnetic. When the ore is transported to the mineral processing plant, it has a low copper content with no recovery value, and the remaining copper sulfide requires further flotation desulfurization, which has little value locally and increases costs.

When Xinhai Research Institute received a similar ore sample for testing, a detailed plan was formulated before and during the test, resulting in the following mineral processing flowsheet:

Innovation Point A:

Since the iron ore contains recoverable non-magnetic copper minerals, it does not follow the conventional iron ore dry selection and tailing.

Innovation Point B:

Given the brittleness of the copper minerals, a one-stage grinding with two-stage classification was adopted, with a rough discharge particle size from the ball mill, and a flash flotation stage was added in the grinding-classification to minimize copper mineral mudding. Additionally, another flash flotation stage was added before the rough flotation to quickly separate copper minerals with fragile foam.

Innovation Point C:

To minimize the indirect flow of first-stage concentrate tailings to iron products, a scavenging stage was innovatively added to the first-stage concentrate tailings to obtain sulfur concentrate products. This mineral processing technology is rarely seen.

Flotation + Magnetic Separation Process Flowsheet for a Copper-Iron Ore in Peru

For complex multi-ore testing with different ore properties from multiple mining points, Xinhai Research Institute starts with representative ore sampling and formulates a representative sample collection method:

Mining capacity planning design—sampling—different sample combinations for testing—main sample testing, auxiliary sample testing for verification—final mineral processing recommended plan—design—construction—mining according to mining capacity design—ore blending at designated locations in processing plant—mineral processing production.

A sample combination table for a gold mine in Indonesia, resulting in six mixed samples for exploratory mineral processing tests, identifying commonalities, and using one mixed sample as the main for testing, with the other five mixed samples for verification.

| YEAR |

ORE SECTION A |

ORE SECTION B |

COMPREHENSIVE GRADE |

REMARKS |

| FAULT GOUGE |

PRIMARY ORE |

FAULT GOUGE |

PRIMARY ORE |

OXIDE ORE |

OXIDE ORE |

| WEIGHT RATIO % |

GRADE G/T |

WEIGHT RATIO % |

GRADE G/T |

WEIGHT RATIO % |

GRADE G/T |

WEIGHT RATIO % |

GRADE G/T |

WEIGHT RATIO % |

GRADE G/T |

WEIGHT RATIO % |

GRADE G/T |

| 1st YEAR |

Second half |

0 |

0 |

30 |

16.81 |

0 |

0 |

0 |

0 |

70 |

6.13 |

0 |

0 |

9.33 |

300tpd mining and mineral processing production |

| First half |

0 |

0 |

30 |

16.81 |

0 |

|

10 |

13.8 |

40 |

6.13 |

20 |

16.05 |

12.09 |

300tpd mining and mineral processing production |

| 2nd YEAR |

Second half |

0 |

0 |

30 |

16.81 |

10 |

1.86 |

10 |

13.8 |

0 |

6.13 |

20 |

16.05 |

11.66 |

300tpd mining and mineral processing production |

| First half |

0 |

0 |

25 |

16.81 |

10 |

1.86 |

25 |

13.8 |

0 |

6.13 |

20 |

16.05 |

12.27 |

300tpd mining and mineral processing production, and new 300tpd plant construction |

| 3rd YEAR |

Second half |

0 |

0 |

50 |

16.81 |

10 |

1.86 |

35 |

13.8 |

0 |

0 |

5 |

16.05 |

14.22 |

300tpd mining and mineral processing production, and new 300tpd plant construction |

| First half |

0 |

0 |

50 |

16.81 |

10 |

1.86 |

40 |

13.8 |

0 |

0 |

0 |

0 |

14.11 |

(300+300)tpd mining and mineral processing production |

| 4th-8thYEAR |

Second half |

0 |

0 |

50 |

16.81 |

10 |

1.86 |

40 |

13.8 |

0 |

0 |

0 |

0 |

14.11 |

(300+300)tpd mining and mineral processing production |

| First half |

0 |

0 |

50 |

16.81 |

10 |

1.86 |

40 |

13.8 |

0 |

0 |

0 |

0 |

14.11 |

(300+300)tpd mining and mineral processing production |

02

Providing Accurate Experimental Research for over 70 Types of Minerals

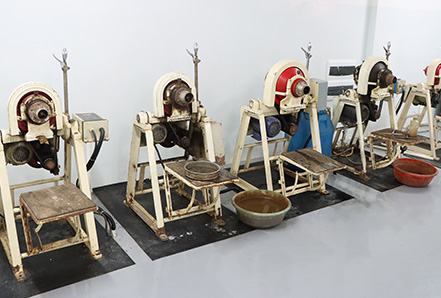

Xinhai Laboratory is equipped with modern advanced equipment, including crushing, fine grinding, roasting, drying, spectrometer, atomic fluorescence spectrometer, atomic absorption spectrophotometer, infrared mineral analysis detection, and a complete set of accessories.

The Mineral Processing Laboratory has a sample crushing room, rock and mineral identification, Bond grinding work index test, intelligent laser particle size detection, and facilities for gravity separation, magnetic separation, flotation, cyanide leaching and adsorption, bacterial oxidation, acid leaching, hydrometallurgy, special mineral processing, heap leaching, tailings thickening and dry discharge, which can provide reasonable experimental research for various mineral processing methods.

-

Flotation Lab

-

Leaching Test Area

-

Magnetic Separation Lab

-

Gravity Separation Lab

-

Grinding Lab

-

Particle Size Analysis Test Area

03

Equipped with First-class Comprehensive Utilization of Minerals Test and Pilot Center

The Xinhai Comprehensive Utilization of Minerals Test and Pilot Center covers an area of about 2000m³, aiming to become a fist-class test center both domestically and internationally. The center is equipped for small-scale testing and semi-continuous industrial testing and also hosts a postdoctoral mobile workstation, which provides advanced research opportunities. It collaborates with multiple universities to establish industry-university-research bases. This center is dedicated to solving current technical challenges in the mine industry, promoting the comprehensive utilization of minerals, and striving to become a leading mineral processing research base in China.

In addition to necessary crushing, screening, grinding, classification, dewatering, and filtration equipment for routine testing, the center is also equipped with gravity separation, washing, flotation, chemical mineral processing, magnetic separation, electric separation, and color sorting test equipment. These devices and processes have been innovatively improved and developed based on actual mineral separation needs.

-

Continuous Flotation

-

Wet Permanent Magnet Magnetic Separation

-

Chute Gravity Separation

-

Shaking Table Gravity Separation

-

Crushing Production Line

-

Slurry Dewatering Treatment

04

Special Departments Ensure Achievement of Test Indicators

Xinhai has established a dedicated Solution Commissioning Department to ensure that all technical indicators for mineral processing tests, assays, and equipment commissioning meet the agreed standards. Xinhai's integrated team handles test research, mine design, and on-site commissioning seamlessly, helping clients achieve the expected recovery rates for their mine projects, ensuring that all process indicators meet requirements, and guaranteeing the stable operation of the processing plant, thus maximizing the overall benefits of the mine.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080