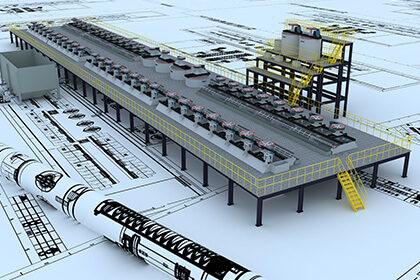

The modern mining enterprise benefits from leading technologies, which are embodied in customized and rational process flow, and high-quality equipment. Xinhai is fully aware of the importance of technology for the development of an enterprise. Therefore, it has mine research institute, mine design institute and mechanical design institute three departments, which provide strong technical support for the smooth development of sales and the comprehensive implementation of "mineral processing EPC+M+O service".

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080