Gravity separation is to make the mineral loose and stratification by depending on the fluid power and mechanical force according to the differences of mineral density and particle size, so as to get the products with the different density or different particle size. The medium (air, water/heavy liquid or suspension) is the necessary factor for gravity separation method except for all sorts of gravity separation equipment. With the help of gravity (the centrifugal force is the main force if in the centrifugal field), mechanical force and medium effect, the particle size with different density will produce different movement speed and movement, then realize the separation.

According to the principle of gravity separation, the form of medium movement and the purpose of operation, the common gravity separation methods mainly include jigging separation, shaking table separation, chute separation, dense media separation and hydraulic/wind power classification.

Use the table of contents below to navigate through the guide:

01Jigging separation

Jigging separation refers to the separate the material according to the density difference in the vertical lifting variable speed medium flow.

In the process of jigging separation, water movement includes the vertical lifting variable pulsating flow and horizontal flow. For the vertical rising water in the jig, the different particles have different moving speed. Those heavy minerals are behind those light minerals in the rising process, and when the ore grain is in the reverse movement, the heavier particles will be larger velocity in static or falling water, thus forming the layering of light and heavy ore grains: the particles with large density are in the lower layer, while the particles with small density are in the upper.

According to the different equipment structure and water movement mode, the jig used in the jigging separation can be roughly divided into the following types: piston jig, diaphragm jig, air pulsation jig, moving screen jig. Among them, the metal mineral processing plant usually adopts diaphragm jig.

02Shaking table separation

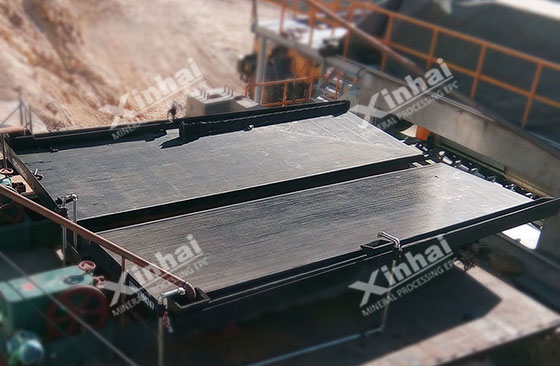

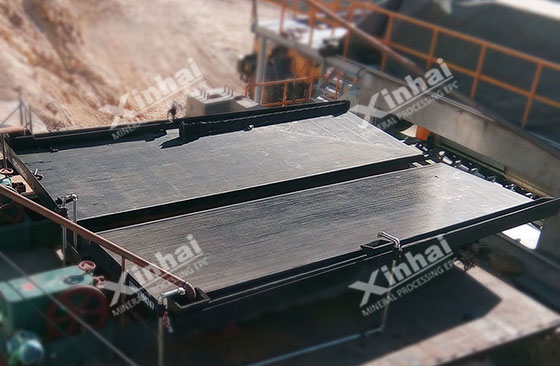

The shaking table separation is to separate the material by making use of the combined action of asymmetric reciprocating motion of shaking table and the water flow of the thin inclined plane according to the different density. The shaking table is common equipment in the gravity concentrator, and it has the features with high enrichment ratio, easy to obtain the final tailings while separating the finial tailings and effectively deal with granular materials.

When the shaking table separates the material with large density, the effective separation size range is 3-0.02mm; When the shaking table separates the material with small density, the upper limit of feed size can reach 10mm. When separating the of tine ore and wolframite, the lower limit of particle size can be up to 0.4mm.

● According to the different equipment structure, the shaking table can be divided into 6s shaking table, yunxi type shaking table, spring shaking table, suspended multi-layer shaking table and table floating shaking table;

● According to the different particle sizes, the shaking table can be divided into sand shaking table and mud shaking table, and the sand shaking table can be further divided into coarse sand shaking table and fine sand shaking table.

As an efficient gravity separation equipment used for fine ore separation, the shaking table is widely used for the tungsten, tin, tantalum, niobium and other rare and precious metal ores. Besides, the shaking table is also used for the separation of iron ore and manganese ore. In recent years, the shaking table can also be used to recover iron ore from the tailings of magnetic separation plants and to separate non-metallic minerals, such as mica.

03Chute separation

Chute separation is to separate the material by using the water flow in the chute. The slurry is sent to the chute with a certain inclination angle, the ore particles finish the laying under the action of the water flow momentum, the gravity and centrifugal force of ore particle and friction force. Because the ore particles are stratified according to the density. Because the velocity distribution of water flow in the trough is large at the top and small at the bottom, the ore particles with a higher density are concentrated in the lower layer, and move forward slowly along the bottom of the trough due to the less momentum of water flow and the greater friction at the bottom. The ore particles with lower density are concentrated in the upper layer, and are carried by the water flow to flow out of the trough at a faster speed. Then, two products with different densities can be obtained by blocking the flow by layers, namely, concentrate and tailings.

● According to the force exerted on the ore particles, the chute can be divided into gravity chute and centrifugal chute.

● According to the feeding size, the chute can be divided into the coarse-grain chute, ore sand chute and mud chute. Coarse-grain chute and ore sand chute are mainly used for gold, platinum, tin and other rare metal placers; Mud chute is often used for tungsten, tin and other minerals.

04Dense media separation

Dense media separation is to crush the ore to a certain size, put into the medium whose density is higher than water (namely dense medium). According to Archimedes buoyancy principle, the ore particles, whose density is lower than the density of the medium, will float, and the ore particles, whose density is higher than the density of the medium, will sink.

Dense media separation is mainly determined by the grain density of the ore. The grain size and shape of the ore have little influence on the dense media separation, so the separation accuracy is relatively high, and the density difference that can be separated is small (such as 0.1g/cm3), the range of the feeding size is large, and the processing capacity is large.

In general, the dense media separation is featured with coarse separating particle size, large processing capacity, strong adaptability to the change of ore feeding, high dressing index and low dressing cost. However, slime and fine grains should be removed before the ore is separated, and the medium preparation and medium purification & recovery system should be equipped.

05Hydraulic/wind power classification

When the dispersed materials settle in the air or water, the particles with different particle sizes and shapes have different settling speeds due to the different medium resistance that they are subjected to. At this time, the materials are separated according to the particle size, which is called hydraulic/wind classification.

● Hydraulic classification is the process of dividing the wide-grade particle group into two or more narrow-grade groups according to the different settling velocity of ore particles in the water;

● Wind classification process is relatively complex and has lower processing efficiency, it is mainly used for the fine particle classification and dry dust collection before dry closed-circuit grinding, dry separation. Because the density of air medium is lower and the effect of wind separation is not good, so the particle size of feed products is generally 1.5-0.005mm, and the particle size of some fibrous and flaky products can be larger. For example, the maximum particle size of mica can be up to 3mm.

In the practice, the gravity separation method is favored by many concentrators because of low production cost, simple equipment structure, low environmental pollution and strong applicability. However, the determination of the gravity separation method should be considered the ore properties, the process requirements, production conditions, investment budget and other factors. It is suggested that every mineral processing plant should carry on the mineral processing test first, then determine the ideal gravity separation method according to the scientific and reasonable test results, strive for the ideal technical indexes and economic benefit.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE