Barite is a common mineral of barium, and the elements of barite are barium sulfate, the BaO accounts for 65.7% and SO3 accounts for 34.3%. It is an important industrial raw mineral material for making barium and barium compounds.

Taking the barite deposit in China as an example, it can be divided into four types: sedimentary deposit, volcano-sedimentary deposit, hydrothermal deposit, and residual deposit. According to ore types, raw ore properties, mine scale and application, the common barite mining processes mainly include handpicking, gravity separation, flotation, magnetic separation and combined barite mining process.

In general, the residual barite ore can be separated by the gravity separation method. The sedimentary barite ore and hydrothermal barite ore associated with sulfide ore and fluorite can be extracted by the gravity separation and flotation method. Below, we will explain to you one by one each barite mining process and barite mining equipment.

Use the table of contents below to navigate through the guide:

01Barite mining process - handpicking process

After the raw ore is extracted, simple handpicking is a common barite mining process for many small barite mines. Some barite mines have a high geological grade and stable quality, so the qualified barite products can be selected by handpicking according to the difference in the color and density between barite and associated minerals. For the rich barite ore selected by hand, the grain size shall be 30-150mm, and the BaSO4 shall be larger than 95%, generally larger than 92%. In general, the simple handpicking process is easy to operate and can be carried out without barite mining equipment. This barite mining process is suitable for the small-scale barite mining plant, but it also has the disadvantages of low productivity, high ore grade requirements and serious resource waste.

02Barite mining process – gravity separation process

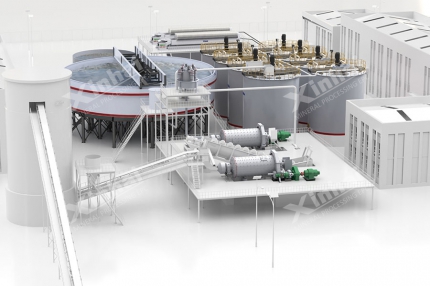

This barite mining process is mainly based on the density difference between barite and associated minerals, including ore washing, screening, desliming, jigging, shaking table, which is mostly used to treat residual barite ore.

After the raw ore is treated with washing, screening, crushing, classification and desliming, the high-quality barite concentrate can be obtained by jigging and shake table. The crushing stage adopts the jaw crusher and impact crusher, the fine crushing stage adopts the double roll crusher. The separation stage adopts a heavy medium rotary drum separator, cone classifier, jig or shake table. The heavy medium separation and jigging separation can be used when the particle size of barite is larger than 2mm, but the upper limit of particle size of heavy medium separation is 50mm, and the upper limit of wet and dry jigging separation is about 20mm. The shake table can be used for separation when the particle size of the barite is less than 2mm, but he hydrocyclone must be used to remove the mud before the separation, so as to improve the separation effect.

03Barite mining process – flotation process

The specific gravity of the barite is large, generally 4-4.6, and it also has a good floatability. The barite flotation process is mainly used to separate the sedimentary barite and hydrothermal barite ore associated with sulfide ore and fluorite based on the difference of surface physical and chemical properties between barite and associated minerals.

Taking the barite ore in China as an example, the barite deposits are featured with more lean ore and less rich ore. More than 80% of the proven reserves are associated with other minerals. The flotation method must be used for the separation of fine barite ore and gravity separation tailings. The main barite flotation processes are positive flotation process and reverse flotation process, in which the purpose of the reverse flotation process is to remove the alkali sulfide.

As a common salt mineral, the barite flotation process can be divided into two types according to the form of adsorption: one is to use fatty acid alkyl sulfate, alkyl sulfonate and other anion collectors to adsorb on the surface of barite mineral in the form of chemical adsorption, so as to separate from the other associated minerals. Another is to use an amine collector to float barite in the form of physical adsorption. The amines collector has low efficiency and is very sensitive to the influence of slime, so it is suggested to adopt the anionic collector in this barite mining process. In general, add the NaOH to the ball mill, adjust the pH value to 8-10, and add the sodium silicate to the slurry as the regulator, then use the oleic acid collector in the barite flotation process under the condition of 40%-50% solid concentration.

04Barite mining process – magnetic separation process

The barite magnetic separation process is mainly based on the surface magnetic difference between barite and iron oxide minerals, which is widely used to separate the iron-containing barite. Themagnetic separation process is often used as the combined process with gravity separation, which can produce the barite a material of barium-based drugs requiring very low iron content.

05Barite mining process – combined process

The combined barite mining process of gravity separation and flotation is often used for the barite associated with sulfide ores. For the flotation-gravity separation process used to treat the barite-quartz-calcite ore, add the sodium silicate and collector into the flotation tank of flotation machine for removing the quartz, and obtain the barite-calcite mixed ore, and adopt jig, shake table to obtain the barite concentrate based on the density difference between gangue minerals (such as calcite) and barite.

The early mining barite ore is mostly high-grade ore, which is usually separated by the low-cost and low technical handpicking or gravity separation process. However, with the low grade of barite ore and the complex ore properties, magnetic separation, flotation and combined barite mining processes have been widely used in barite mining. It is suggested that each mine owner should make a scientific and reasonable barite mining process according to the beneficiation test report, avoiding unnecessary economic losses.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE