Are you looking for a more efficient scheelite ore extraction process? Scheelite is an important source of tungsten. It is widely used in hard alloys, electronic components, and the defense industry, holding very high industrial value. The scheelite price depends on tungsten content, ore quality, and market demand. However, scheelite mineral is often found with complex gangue minerals, making extraction difficult.

This article provides an in-depth examination of the beneficiation and extraction process for scheelite, including common flotation methods, key equipment, and optimization strategies. By reading it, you will not only learn how to improve tungsten recovery rates but also discover an efficient solution path tailored to your own mine.

Use the table of contents below to navigate through the guide:

01In-Depth Analysis of Scheelite Beneficiation Process

The beneficiation of scheelite stone is a key step in the tungsten extraction process. Its scientific soundness and rationality directly affect the subsequent tungsten recovery rate and product quality.

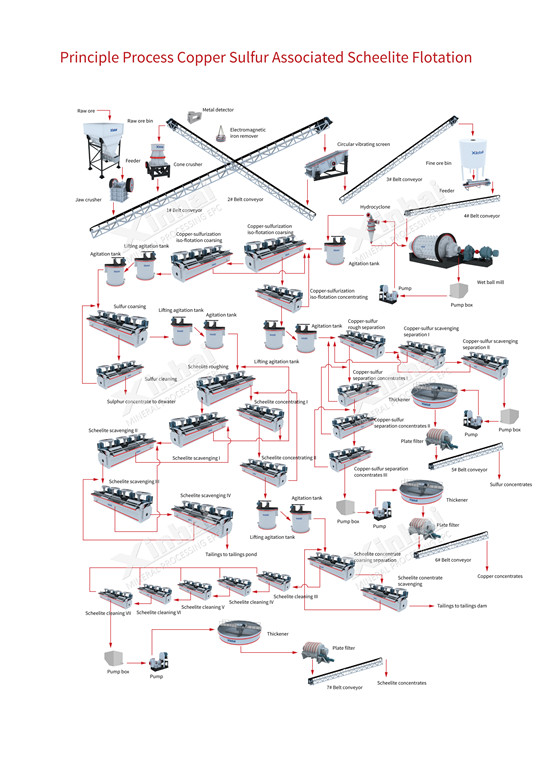

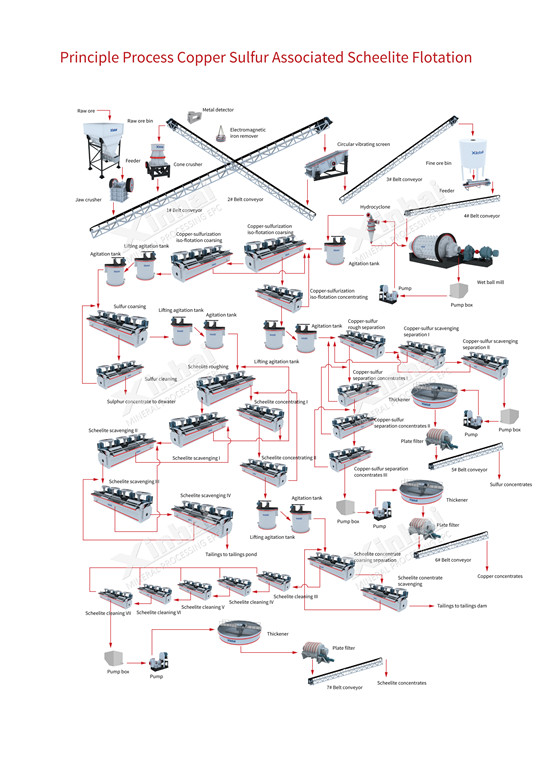

Scheelite is often found with various sulfide minerals, with molybdenite being particularly common. To prevent sulfide minerals from interfering with scheelite flotation, the general beneficiation process follows the principle of "floating sulfide minerals first, then floating scheelite." This preferential flotation process effectively separates sulfide minerals from scheelite, laying a good foundation for efficient scheelite flotation later.

Scheelite flotation is carried out in an alkaline medium. The pH of the pulp is a key factor affecting flotation performance. Sodium carbonate and sodium hydroxide are usually used to adjust the pulp pH to a range of 9-10.5. In this pH environment, scheelite maintains good floatability, while some gangue minerals are suppressed.

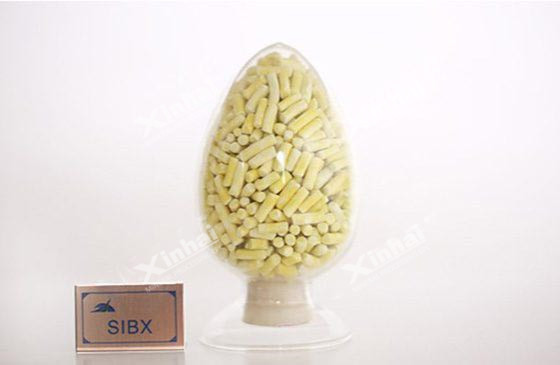

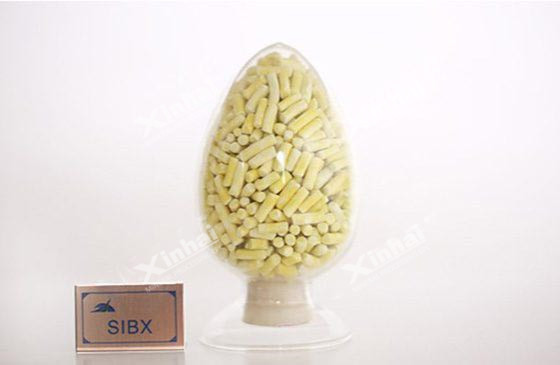

During flotation, depressants play a crucial role in improving selectivity. Commonly used depressants include sodium silicate (modulus 2.2-3), saponin gum, tannic acid, and various phosphates.

Collectors are another important reagent in scheelite flotation. Commonly used collectors include oleic acid, sodium oleate, tall oil, and oxidized paraffin soap. These collectors have good surface activity, can selectively adsorb onto the scheelite surface, making it hydrophobic, and allowing it to attach to air bubbles and float.

It's worth noting that these collectors themselves have frothing properties, so usually no additional frother is needed in the actual flotation process. This simplifies the flotation process and lowers reagent costs.

Although scheelite ore has good floatability, actual ores often contain calcium-containing gangue minerals with similar properties, such as calcite, fluorite, and apatite. These gangue minerals have surface properties similar to scheelite, making them easily adsorbed by collectors, too. This complicates the flotation process and lowers the grade of the scheelite concentrate.

To solve this problem and improve flotation selectivity, a common and effective method is to add multivalent metal salts (like ferrous sulfate) to the sodium silicate. This combination significantly enhances the depression effect on calcium-containing gangue minerals without affecting the floatability of scheelite. This greatly improves scheelite flotation performance, yielding a higher-grade scheelite concentrate.

Furthermore, heating the pulp is also an important measure to improve scheelite flotation. The Petrov method is a classic example of using this principle. This method heats the pulp to 70-90°C while adding a large amount of sodium silicate.

Under the combined action of high temperature and abundant sodium silicate, the collector adsorbed on the calcite surface is desorbed. Calcite loses its floatability and sinks, while scheelite maintains good floatability and is selectively floated out. This further improves the separation effect between scheelite and gangue minerals.

02Scheelite Ore Dressing Equipment

The choice of extraction equipment is closely related to the scheelite beneficiation process. High-quality and suitable equipment ensures the smooth progress of the beneficiation flow and improves production efficiency. As a world-renowned mining equipment manufacturer and mining solutions provider, Xinhai Mining has a complete equipment line suitable for all stages of scheelite extraction. It can provide strong support for your scheelite project.

1. Crushing and Grinding Equipment

In the crushing and grinding stage, the first step in scheelite extraction, jaw crushers offer advantages such as a high crushing ratio, high crushing efficiency, and strong adaptability. They can effectively break large chunks of scheelite stone into small particles, meeting the requirements for the next process. Cone crushers are suitable for medium- to fine-crushing of scheelite. They operate smoothly with low noise and produce well-shaped crushed products, further improving the quality of the crushed ore. Ball mill grinder is used for the grinding operation of scheelite.

2. Flotation Equipment

In the flotation stage, the flotation machine is the key equipment. Xinhai's large intelligent flotation machines feature a unique tank structure and impeller design, ensuring the full mixing of pulp, reagents, and air to form stable and evenly distributed bubbles. These flotation machines offer high flotation efficiency, good selectivity, and strong adaptability to different ore properties. They can effectively separate scheelite from gangue to obtain a high-grade scheelite concentrate.

3. Thickening and Dewatering Equipment

In the dewatering stage, press filter and centrifuges play important roles. Filter presses have high dewatering efficiency, producing filter cakes with a low moisture content. They effectively separate the solid and liquid phases in the scheelite concentrate, facilitating its storage, transportation, and further processing. Centrifuges are suitable for dewatering fine scheelite concentrates. They offer a fast dewatering speed, a compact structure, and easy operation, further enhancing the dewatering effect of the concentrate.

Additionally, Xinhai provides a range of auxiliary equipment, such as vibrating screens, spiral classifiers, and magnetic separators. These can be matched with the main equipment based on the actual needs of the scheelite extraction process to form a complete and efficient production line.

Conclusion

The Scheelite beneficiation process relies not only on scientific flotation methods but also on reliable equipment and thorough site management. With rich industry experience, Xinhai Mining can provide clients with:

Beneficiation Test Research and Process Design

Full Range Equipment Manufacturing and Procurement

Installation, Commissioning, and Personnel Training

Mine Management and Operation & Maintenance (EPC+M+O)

Through its one-stop service, XinhaiMining helps clients achieve full-process value enhancement from ore to concentrate, ensuring maximum returns on project investments.

Contact us to obtain your scheelite beneficiation solution and transform resources into tangible profit

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE