Gold mining is a complex and systematic process. Getting from raw ore to high-purity gold involves multiple stages and a complete set of equipment. In regions rich with placer gold deposits, small-scale miners and some mid-sized operations often use a Gold Wash Plant for physical concentration. This allows for a quick start and helps produce gold material.

For hard rock deposits or medium to large mines focused on long-term, stable output, building a Gold Processing Plant is better suited to meet industrial production needs and economic return. Both are essential solutions in the gold production chain, but differ significantly in process flow, target products, and suitable applications. Keep reading to learn the key differences.

Use the table of contents below to navigate through the guide:

01What Is a Gold Wash Plant?

A Gold Wash Plant is designed to process placer deposits or alluvial gold through physical gravity separation. This type of equipment targets loose minerals found in riverbeds, sand, and gravel. It uses a series of physical separation methods to achieve initial gold concentration. A wash plant is a mechanized, large-scale version of the traditional "gold pan."

It's important to note: a wash plant does not produce pure gold. It makes "gold-rich sand" (concentrates). Further processing is needed to extract the pure gold.

02What Is a Gold Processing Plant?

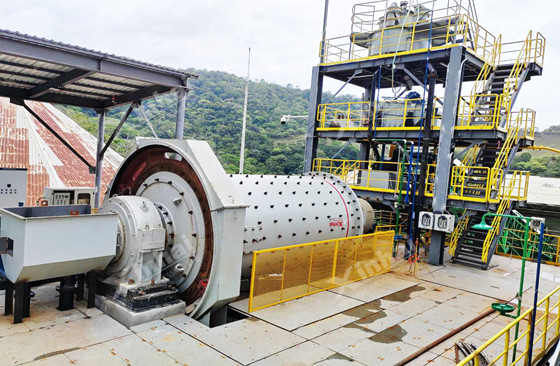

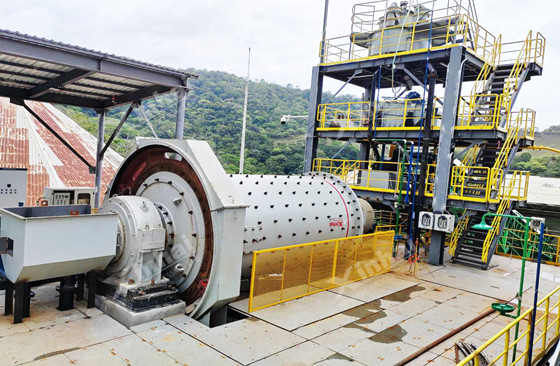

A Gold Processing Plant is an integrated facility that covers the entire production chain from ore to finished gold. It is far more complex in design and operation than a wash plant. This type of plant mainly processes hard rock deposits and complex ores. It involves a variety of physical, chemical, and metallurgical processes.

Gold processing plants usually require a larger investment. However, they offer higher production capacity and better recovery rates, making them more suitable for long-term, stable mining operations.

03Gold Wash Plant vs. Gold Processing Plant: 6 Key Differences

In gold mining, gold wash plants and gold processing plants are two common types of facilities. They differ significantly in the kind of ore they process, technology, final product, cost, and environmental requirements. Here are six key differences to help miners and investors choose the right solution.

1. Type of Ore Processed

• Wash Plant: For placer deposits. Ore is found in riverbeds, glacial sediments, or gravel layers. Gold particles are loose and don't require blasting.

• Processing Plant: For hard rock deposits. Gold is locked in quartz veins or other rocks, requiring blasting, crushing, and grinding to release it. It can also further purify concentrates from a wash plant.

2. Core Technology

• Wash Plant: Uses physical gravity separation. This includes trommel screening, sluice box trapping, jigging, and centrifugal concentrators for fine gold.

• Processing Plant: Combines physical, chemical, and metallurgical methods. Steps include crushing, grinding, gravity separation (sometimes), chemical processes like cyanidation (CIP/CIL) or flotation, and smelting/refining to produce pure gold.

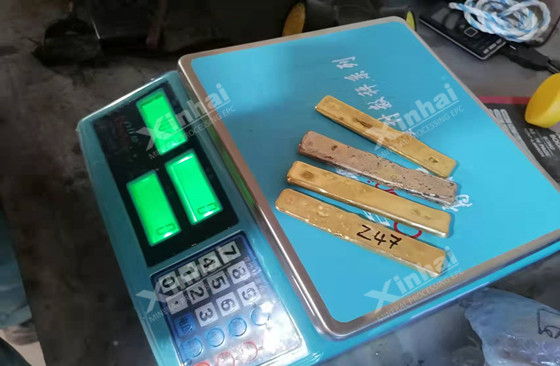

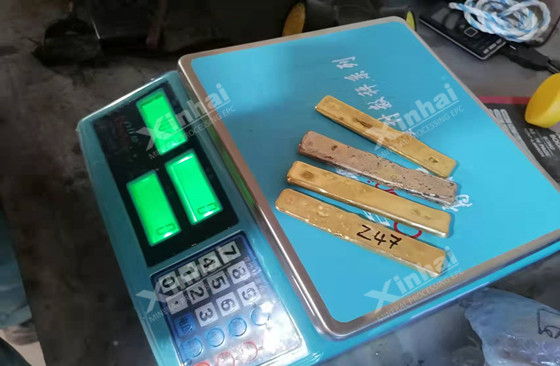

3. Final Product

• Wash Plant: Produces gold concentrates (50–90% gold), which still contain impurities and need further refining.

• Processing Plant: Produces high-purity gold, such as doré bars (>80% purity) or even pure gold, which can be sold directly.

4. Complexity & Automation

• Wash Plant: Relatively simple. Modular design, easy to relocate. Ranges from small manual setups to fully automated systems.

• Processing Plant: Complex process flow. Usually fixed and permanent. Requires strict chemical control and automated monitoring. Higher technical demand.

5. Investment & Operating Cost

• Wash Plant: Lower investment. Small systems start in the tens of thousands of USD; large systems can cost a few million. Operating costs mainly include fuel, water, and labor.

• Processing Plant: High investment, ranging from tens to hundreds of millions of USD. Operating costs include reagents, energy, and environmental maintenance.

6. Environmental Factors

• Wash Plant: Main issues are water usage and tailings management. Focus is on water recycling and tailings storage.

• Processing Plant: Involves more complex environmental concerns, such as chemical management (e.g., cyanide), tailings dam construction, and air pollution control. Must comply with stricter regulations.

It's worth noting that in real-world mining projects, wash plants and processing plants often work together rather than being alternatives. A wash plant can serve as a pre-concentration unit for a processing plant. A complete processing plant may also include a wash plant or gravity separation unit as its initial stage. This integrated approach can improve overall recovery and reduce reagent consumption.

04How to Choose the Right Solution for Your Project?

Choose a Gold Wash Plant if:

You have a placer deposit, a limited budget, want to start production quickly, need mobility, only require initial gold concentration, prefer to avoid chemicals, and enjoy simpler permits.

Choose a Gold Processing Plant if:

You have a hard rock deposit, sufficient funding, aim for long-term and large-scale production, want to produce directly marketable high-purity gold, and have the technical capacity to handle chemical processes and stricter environmental standards.

Xinhai Mining provides mature plant design and complete Gold Processing Plant solutions, including mineral testing, process design, equipment manufacturing, and EPC services. We help clients achieve large-scale, stable production while ensuring high recovery and environmental compliance.

If you plan to build or upgrade your gold processing facility, contact Xinhai today for a customized solution!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE