The design of a gold concentrator is critical as it directly affects the economics, environmental impact, safe operations and long-term sustainability of the entire mining project. The design of a gold concentrator should follow a series of principles to ensure its efficient, economical, environmentally friendly and sustainable operation. Here are some key design principles that a gold concentrator should follow:

.jpg)

Use the table of contents below to navigate through the guide:

01Economy of gold concentrator

The economics of gold concentrator design is reflected in many aspects, including investment cost, operating efficiency, resource recovery rate, environmental impact, technological innovation and market adaptability. Construction costs should be considered during design, including civil construction, equipment procurement, installation and commissioning, etc. By optimizing the design, unnecessary investment is reduced, such as rationally planning the plant layout, selecting cost-effective equipment, and utilizing existing infrastructure, while ensuring the efficiency of the mineral processing process to increase the gold recovery rate.

02Technical adaptability of gold concentrator

The design of the concentrator should be adapted to the characteristics of the ore, including the type of ore (such as quartz vein type, sulfide type, etc.), the form and distribution of gold in the ore (such as particle size, shape), the hardness, grindability, and magnetism, etc., these parts determine the required mineral processing method, mineral processing efficiency, selection of crushing and grinding equipment and design of the process flow. The design should be flexible in response to changes in ore properties.

With the development of automation and intelligent technologies, the design of mineral processing plants should consider integrating these technologies. Use automation and intelligent technologies to improve production efficiency, reduce manual operations, and improve the accuracy of data collection and process control.

According to market demand, the design should ensure that the output gold products meet quality standards, such as purity, particle size, etc., and also consider future changes in market demand for gold to ensure that the concentrator can flexibly adjust production strategies to adapt to market fluctuations.

03Environmental protection and sustainability of gold concentrator

Designs should comply with environmental regulations to reduce environmental impact, including wastewater treatment, air emission control, solid waste management and noise control. At the same time, resource recycling and energy efficiency should be considered.

From the perspective of energy consumption, the design of gold concentrators should consider the optimization of energy consumption, adopt energy-saving equipment and processes, and possible energy recovery technologies. According to different water resources conditions of mineral processing plants, the use of water resources should be reasonably planned, including the design of circulating water systems, to reduce the use of fresh water and wastewater discharge.

04Other aspects of gold concentrator

Ensuring the safety of the mineral processing plant is an important design principle, including the safety of employees, safe operation of equipment, and preventing accidents. Depending on the location of the plant, potential risks should be identified during the design stage and corresponding risk mitigation measures should be formulated.

Mineral processing equipment and systems should have high reliability and durability to reduce downtime and repair costs. Possible future technology upgrades and capacity expansions should be considered during the design phase to allow for flexible adjustments when market demand changes.

In addition, it should be ensured that the gold concentrator is designed and operated in compliance with all relevant national and local laws and regulations, including mining permits, environmental standards and labor regulations.

The design of a gold concentrator is the key to the success of a mining project. It not only requires comprehensive consideration of economy, technical adaptability, environmental sustainability and regulatory compliance, but also relies on the exquisite skills and rich experience of the design team. An excellent design team can conduct in-depth analysis of ore characteristics, tailor-made efficient mineral processing solutions, and provide professional guidance on the application of automation and intelligent technology to ensure the efficient operation and intelligent level of the mineral processing plant.

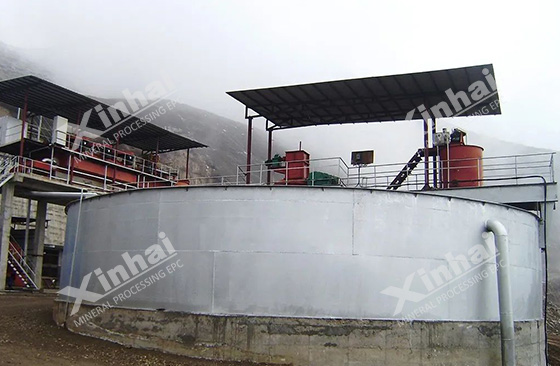

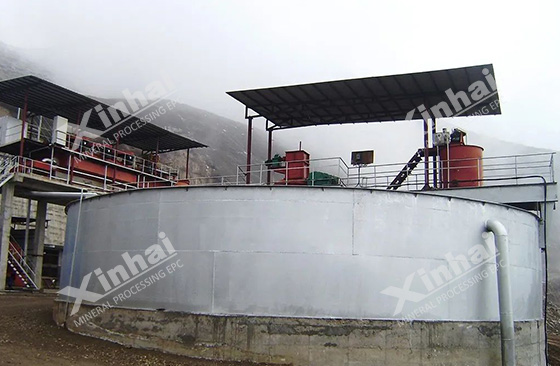

05Part of Xinhai Mining Gold Ore Concentrator Project

1. Guinea 15000tpd gold ore concentrator

2. Guinea 6000tpd gold ore concentrator

3. Shandong 6000tpd gold ore dressing plant

4. Mongolia 1.2 million tpa gold concentrator

5. Henan 3000tpd gold ore dressing plant

6. Heilongjiang 2000tpd gold ore dressing plant

7. Laos 2000tpd gold ore dressing plant

8. Tanzania 1200tpd gold ore concentrator

9. Burundi 1200tpd gold ore concentrator

10. Gansu 1000tpd gold ore dressing plant

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE.jpg)