In today’s mining industry, a mineral processing laboratory serves as a critical foundation for ore evaluation, process development, and project decision-making. Its work influences not only the technical feasibility of a flowsheet but also the long-term economic performance of a mining operation. Through years of project experience, including practical cases from Xinhai Mining’s Mineral Processing Research Institute, several core attributes have emerged that define what makes a laboratory truly reliable and engineering-oriented.

Use the table of contents below to navigate through the guide:

01Comprehensive Infrastructure and Thoughtful Laboratory Layout

A high-level mineral processing laboratory begins with well-designed zoning. Clear functional boundaries prevent cross-contamination, streamline workflows, and help maintain the accuracy of experimental outcomes.

A typical scientific layout includes:

Sample preparation area for crushing, grinding, and sample division

Particle size analysis area for grain-size and distribution characterization

Gravity separation area equipped for jigging, tabling, and spiral tests

Magnetic separation area with LIMS, HIMS, and HGMS setups

Flotation area for batch, locked-cycle, and continuous flotation programs

Chemical & mineralogical analysis zone for ICP-OES, XRF, XRD, SEM work

Reagent preparation room

Pilot plant for semi-industrial verification

In practice, laboratories such as the one operated by Xinhai Mining illustrate how a clear zoning strategy significantly reduces sampling errors and improves reproducibility in multi-stage testwork programs.

02Equipment Completeness and Test Accuracy

Equipment defines the scope of what a laboratory can do. A complete technical chain—from crushing to pilot-scale verification—allows a laboratory to provide engineering-grade guidance.

Common elements include:

Sample preparation systems ensuring representative and uniform samples

Gravity separation equipment (jigs, shaking tables, spirals, centrifugal units)

Multiple flotation machine models for different ore types and scales

Wet, dry, and high-gradient magnetic separators

Laser particle-size analysis instruments

Advanced mineralogical tools (ICP, XRF, XRD, SEM)

Many research institutions, including Xinhai’s, have gradually expanded their equipment systems to handle increasingly complex ores, ranging from refractory gold to ultra-fine polymetallic materials.

→ Learn more about Xinhai Mining’s mineral testing services

03Systematic Test Capability and Professional Technical Competence

A qualified mineral processing lab must demonstrate three core capabilities: end-to-end testing workflow competence, the ability to treat challenging ores, and the application of advanced data modeling and simulation tools. Next, we delve into the details.

1. Complete Test Workflow

An outstanding laboratory must support the whole chain of mineral processing studies, including:

Initial ore properties and characterization

Gravity, magnetic, and flotation testing

Locked-cycle and continuous closed-circuit testing

Scale-up and pilot verification

The value of this full-process capability lies in the fact that the laboratory’s output can be directly utilized for feasibility studies, flowsheet engineering, and equipment selection. Many global mining projects have relied on such structured workflows to shorten design cycles and reduce uncertainty in early-stage decision-making.

2. Capability to Address Refractory Ores

Modern deposits are often lower-grade and more complex in nature. Laboratories must be equipped to handle:

Refractory gold ores requiring specialized leaching routes

Ultra-fine materials that need enhanced flotation or gravity solutions

Polymetallic associated ores requiring selective separation

Oxidized and clay-rich ores prone to dispersion

Strategic minerals, such as spodumene and lepidolite

The Xinhai team conducts metallurgical testing on over 2,000 mineral samples annually, covering polymetallic ores such as gold/copper/lead-zinc, lithium spodumene, graphite ore, iron, manganese, and chromite, as well as rare earths, barite, fluorite, silica sand, and quartz sand. This extensive experience enables the team to swiftly identify processing challenges and deliver efficient solutions.

3. Data Modeling and Simulation Tools

With increasing project complexity, simulation has become a standard part of laboratory practice. Common tools include:

JKSimMet for grinding and classification simulation

Bruno or similar models for crushing circuits

Data visualization, regression analysis, and mass balancing

Predictive parameter optimization

When combined with rigorous test data, simulation improves consistency between test results and industrial production—a trend confirmed by long-term project feedback from various EPC and mining operations.

04Standardized Management and Quality Control Systems

1. Sample Management

Good sample management ensures credibility. Effective systems typically include:

Unambiguous labeling and numbering

Backup retention for traceability

Clean handling procedures to avoid contamination

Full-process logs from receipt to disposal

2. Structured and Engineering-Ready Reporting

At Xinhai, a high-quality test report should include:

Ore characteristics and mineral composition

Single-process test data

Flowchart recommendations and design parameters

Reagent schemes and test conditions

Project-specific optimization recommendations

A comprehensive report not only documents laboratory results but also provides the design team with actionable, field-applicable information.

3.Safety and Environmental Considerations

A responsible laboratory should maintain:

Strict chemical handling protocols

Wastewater and residue disposal systems

Adequate ventilation and flammable/toxic substance safeguards

Regular safety training

For us, ensuring experimental data accuracy is equally important as safeguarding personnel safety and environmental friendliness. Ultimately, safety is the cornerstone of all operations. Only by implementing these systems can a laboratory achieve long-term, stable operation.

05Providing comprehensive process design support for mining projects

A high-level mineral processing laboratory must not only generate test data but also transform it into optimized, practical engineering solutions.

Customized Process Flow Development: Based on ore characteristics and laboratory-scale beneficiation results, XinHai Mining provides tailored process flow designs, including reagent schemes, grinding fineness, flotation conditions, gravity separation parameters, and leaching routes.

Pilot-Scale Testing: Pilot plants validate recovery rates, reagent consumption, and process stability prior to industrial implementation, thereby mitigating investment risks.

Global Project Experience and Field Feedback

A truly outstanding mineral testing center is defined not only by its laboratory capabilities, but also by its ability to apply test results to real-world mining operations.

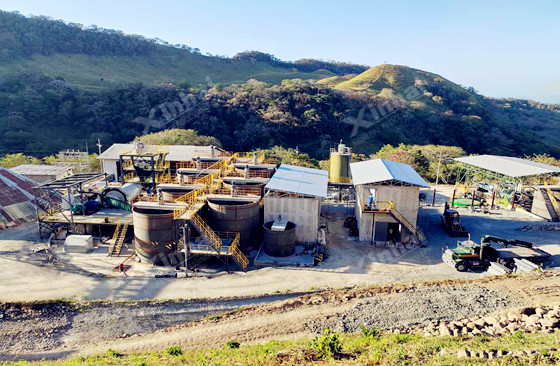

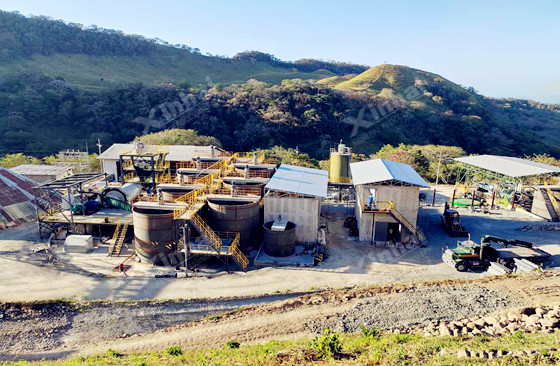

Xinhai Mining has served over 2,000 mineral processing projects across more than 90 countries. Laboratory test results have been validated in real-world gold mines, copper concentrators, spodumene plants, and quartz sand purification projects worldwide.

→ Explore Xinhai’s flotation technology / gold processing projects

Conclusion

A world-class mineral processing laboratory must integrate comprehensive mineral testing, advanced equipment, scientific process simulation, specialized technical expertise, and extensive global experience.

Leveraging these combined strengths, Xinhai Mining's mineral processing laboratory delivers precise test results, reliable process designs, and proven economic benefits—supporting mining projects from initial sample testing through full-scale plant construction.

If your project requires a reliable mineral processing solution, feel free to contact us.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE