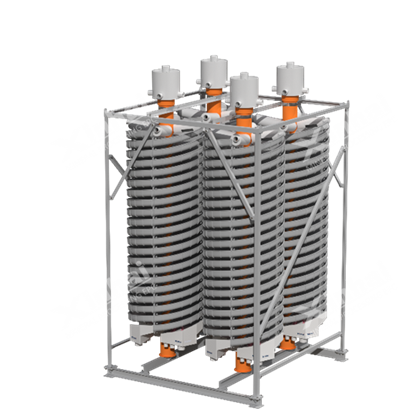

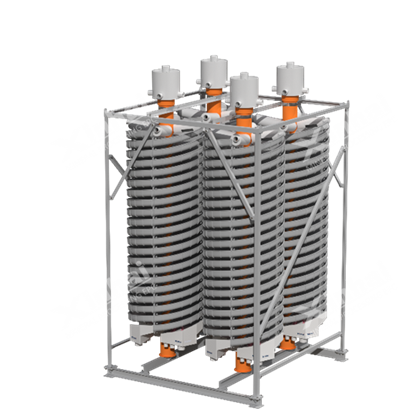

The XH Spiral Chute is an advanced gravity concentrator widely used in metallic ores, placer minerals, non-metallic processing, and tailings recovery. It features an NM500-grade wear-resistant lining that offers excellent resistance to acid, alkali, flame, and cold temperatures (as low as -30°C), with a service life exceeding 20,000 hours. It also provides better anti-aging performance compared to traditional fiberglass chutes. What's more, it is highly energy-efficient and supports flexible configuration. Keep reading to learn more about this robust and dependable gravity separation equipment.

Use the table of contents below to navigate through the guide:

01What Is the XH Spiral Chute?

The spiral chute is one of the earliest forms of gravity separation equipment. It uses gravity, centrifugal force, and other dynamic effects to classify, concentrate, and separate mineral particles. It is ideally suited for processing fine-grained minerals between 0.3–0.02 mm, including:

Metallic Ores: Iron ore (hematite, magnetite), tin, tungsten, tantalum-niobium, gold, and more

Placer Minerals: Heavy minerals such as gold, platinum, ilmenite, and zircon in coastal and river sands

Non-Metallic Ores: Purification of quartz sand, feldspar, and fluorite by removing heavy impurities

Tailings Recovery: Retrieving fine-grained metallic minerals from tailings to improve resource utilization

The XH Spiral Chute is a fully upgraded version of conventional spiral chutes. It combines the convenience of spiral concentrators, the precision of shaking tables, and the efficiency of centrifugal concentrators—effectively solving common issues such as low processing efficiency, weak adaptability, and complex operation.

The following is the core technical parameters of XH spiral chute:

| Parameters | Specifications |

| Diameter | 1200m |

| Pitch | 580mm |

| Capacity per Start | 1.5~2t/h |

| Total Capacity per Unit | 6t/h |

| Service Life | >20,000 h |

02What Makes the XH Spiral Chute Stand Out?

1. Superior Material

Built with high-wear engineering plastic and an NM500 lining, it ensures a service life of over 20,000 hours. It is corrosion-resistant, flame-retardant, and cold-proof, performing reliably even at -30°C. For example, in a 500t/d gold gravity separation project in Russia, extremely low temperatures threatened to delay the construction period. With the XH Spiral Chute, the customer maintained stable mineral processing operations and achieved production targets, earning high satisfaction. Moreover, it resists UV aging and far outlasts traditional fiberglass spiral chutes.

2. Innovative Design

Traditional spiral chutes often face the "sand dune wall" problem, where material piles up and efficiency drops. The XH Spiral Chute uses a double-section 3D spiral design to improve particle looseness, prevent blockages, and increase separation efficiency.

3. Energy-Efficient Performance

We designed the XH Spiral Chute to help customers achieve high output with low investment. Energy consumption is a significant long-term cost in mineral processing. This device uses an entirely physical separation process with no external power required, significantly reducing electricity costs—potentially saving tens of thousands annually. There are no vulnerable parts, which ensures stable operation with minimal maintenance and further cuts labor and repair costs. Despite its simple operation, it delivers strong performance: a single unit can process up to 6 t/h (1.5–2 t/h per head), efficiently meeting large-scale processing demands.

4. Flexible Configuration

The XH Spiral Chute can be tailored to different plant layouts and processing needs:

Multiple head options: 2, 3, or 4 heads available to match capacity requirements

Easy installation: Modular assembly is supported, and a steel frame (for a set of four units) is optional, allowing quick setup with minimal construction work

It is suitable for various applications, including roughing, scavenging, and processing mid-to-low-grade and mid-sized ores, delivering consistent and high-quality separation results.

03How to Operate the XH Spiral Chute?

Operating the XH Spiral Chute is simple. You can safely install the unit on a support frame and ensure it's consistent or fed. During operation, slowly feed a well-mixed slurry of appropriate density from the top. As the slurry flows downward along the spiral, minerals separate by density: heavier minerals move inward, while lighter ones stay outward. Concentrate, middlings, and tailings can be collected easily at the bottom through a splitter. For optimal and consistent performance, regularly check the wear condition of the chute and maintain proper water flow and slurry density.

04XH Spiral Chute in Real Operation

The XH Spiral Chute has proven its effectiveness across multiple applications. For instance, I’ve personally seen how it helped improve recovery rates at a gold processing plant. After integrating the XH Spiral Chute into their production line, the plant saw noticeable improvements in both particle separation accuracy and overall mineral recovery. The result was higher production efficiency and significantly reduced operating costs. Cases like this demonstrate the real value the XH Spiral Chute can bring to any mining operation.

Conclusion

Whether you are separating metallic ores, purifying placer minerals, processing non-metallic ores, or recovering value from tailings, the XH Spiral Chute can help you overcome:

Equipment failure in extreme cold or hot temperatures

Low efficiency and limited capacity of traditional equipment

High energy and maintenance costs eating into profits

Challenging installation due to limited space

The Xinhai XH Spiral Chute is more than just a “more durable chute”—it’s a reliable partner that helps protect your profitability even under the toughest conditions.

Contact us today for a quote or more information!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE