Carbon in leaching(CIL) is one of the main methods of gold beneficiation, which adds activated carbon to the slurry while leaching and adsorbing gold.

Compared with carbon in pulp(CIP), the CIL process can reduce the number of leaching tanks, shorten the process flow, and reduce capital investment and production costs. The CIL process mainly includes six stages of slurry removal, concentration, leaching and adsorption, desorption electrolysis, wet smelting, and activated carbon regeneration.

Use the table of contents below to navigate through the guide:

01Slurry Removal of gold CIL process

Before leaching and adsorbing the cyanide pulp, it is important to remove the wood chips and other impurities in the pulp, which can prevent impurities from adsorbing the gold and blocking the pipeline and carbon screen.

When necessary, a descaling agent can be added to reduce scaling on the surface of the activated carbon and the screen. In general, two removal operations can be set up at the overflow in the first and second stages of grinding and classification respectively.

Main equipment: linear vibrating screen.

02Concentration of gold CIL process

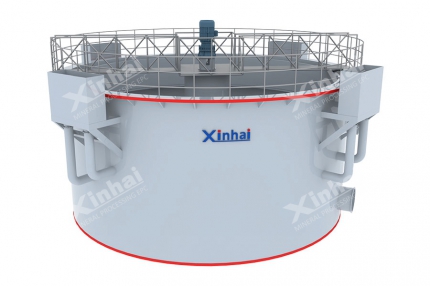

To achieve a proper pulp leaching concentration, the pulp must be dewatered by the thickener before leaching, which would affect the leaching time and the suspended state of activated carbon. When the overflow concentration of grinding and classification is low, it is suitable for concentrated slurry first not direct leaching.

Main equipment: high-efficiency transformed thickener.

03Leaching and Adsorption of gold CIL process

For the CIL process, gold leaching and adsorption operations are carried out at the same time. And the size and quantity of the leaching tank should be decided according to the processing capacity of the plant.

The treated pulp is driven into a high-efficiency leaching tank arranged in a stepped configuration. Generally, 5 to 8 leaching tanks are arranged in series. The first two leaching tanks are filled with cyanide, and the last five leaching tanks are filled with activated carbon.

Sodium cyanide has just been added to the tank with a small amount of leached gold. Therefore, most CIL plants use the first leaching tank as a prepreg tank and the subsequent leaching tank as a leaching adsorption tank.

Each leaching tank is equipped with a carbon screen to separate activated carbon and pulp, which are adsorbed in countercurrent to form gold-loaded carbon. Then, the slurry containing gold-loaded carbon is sent to the carbon extraction screen through an air lifter to separate the slurry and the activated carbon. After that, the clean saturated carbon is fed to the desorption electrolysis system for gold extraction.

04Desorption Electrolysis of gold CIL process

There are many methods of desorption electrolysis. At present, the high-temperature and high-pressure desorption methods are often used. Under the conditions of high temperature and high pressure, anions easily adsorbed by activated carbon are added to the desorption system to replace Au(CN)2- for obtaining gold mud and lean in carbon. The precious liquid obtained by desorption of gold-loaded carbon is recovered by the ionization method to obtain solid gold.

Main equipment: desorption column, pickling tank, desorption tank, and electrolysis tank.

05Wet Smelting of gold CIL process

Gold mud can be directly smelted into gold ingots after simple pickling operations.

06Activated Carbon Regeneration of gold CIL process

The activated carbon after adsorption and desorption needs to be regenerated to restore the original adsorption performance. Usually, the used activated carbon is pickled first to remove the carbonate and other accumulations, and then thermally activated to restore the adsorption activity. Finally, the activated carbon can be recycled again.

The CIL process has strong adaptability to ore type and is suitable for the beneficiation of gold mines with high associated silver and copper content and high-grade large-scale gold mines. Compared with traditional methods, it has the characteristics of simple process, low cost, easy operation, and high gold recovery rate.

Of course, the specific gold ore beneficiation should be determined comprehensively by the nature of the gold ore, the actual situation of the concentrator, and economic benefits.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE