Alluvial gold mines is various in kinds and widely distributed. According to the transport distance, the alluvial gold mines can be divided into residual placer gold, slope placer gold mine, alluvial placer gold mine, riverbed impact placer gold mine, and coastal placer gold mine. Among them, the riverbed impact placer gold mine is common. According to handling force medium, the alluvial gold mine can be divided into aeolian placer gold mine, ice-forming placer gold mine, and aquatic placer gold mine. According to the era of transport, the alluvial gold mine can be divided into deep placer gold deposit, terraced placer gold mine, and river beach placer gold mine. There is very low content gold in the alluvial gold mine. It needs all kinds of gold processing equipment for processing and enrichment. The gravity separation has the characteristic of high-efficiency, energy-saving and environment-friendly. It is the main alluvial gold mining method. Generally, gold and various kinds of associated heavy minerals can be recovered through gravity separation. Then gold and associated heavy sand minerals can be separated through gravity separation, flotation, magnetic separation, and electrostatic beneficiation.

The gravity separation includes washing, screening, gravity separation and concentration in alluvial gold mining methods.

Use the table of contents below to navigate through the guide:

01Washing of Alluvial Gold Mining Method

The aim of washing is to separate the grail, sand and grain oil in alluvial gold mines. It also washes the fine mud and the gold particles. Generally speaking, there are a lot of weathered clay in alluvial gold mines. Gold particles are packed in clay, forming cement block or mud body. If the cement block or mud body is not broken, it will be discharged with waste stones in screening, which reduces the recovery rate of the alluvial gold mine and causes the loss of gold.

Washing is to dissolve mineral sand through mechanical agitation from cement block or mud body. It separates gravel, sand and clay, and washes the clay and gold particles attached to the gravel. Washing operation includes shattering, screening and desliming. It is an important operation of the alluvial gold mining method. It can improve the processing of alluvial gold mine, and advantage for improving the recovery rate of alluvial gold.

02Screening of Alluvial Gold Mining Method

Generally, the large block screening operation is mainly to screen the alluvial mine after washing. Large grails are discharged to improve the efficiency of gold processing equipment. 20%~40% waste stones can be discharged in screening operation.

According to granularity composition parameters of gold in raw ore, the screen sieve pore is determined. At present, the sieve pore for alluvial gold mines is usually 10~20mm. If the fixed chute is used for coarse separation, the sieve pore can be larger, but smaller than 60mm. In fixed concentrator, vibrating screen and grid screen can be used as screening equipment. Cylindrial screen is commonly used in gold dredgers. Wet screen is most used for alluvial gold mining methods. Sieve flush can break the slime and improve the screening efficiency of alluvial gold mine.

03Gravity separation of Alluvial Gold Mining Method

Gravity separationis mainly used in alluvial gold mining method. On the one hand, the alluvial gold has a large proportion and coarse in particle size of 0.074~2mm. On the other hand, gravity separation is economic and simple. It is also the key operation of the alluvial gold mining method. Most waste stones can be discharged in this period, and coarse gold concentrate can be recovered.

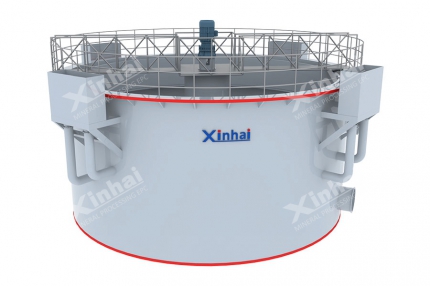

04Concentrating of Alluvial Gold Mining Method

According to different types of alluvial gold, the concentrating operation uses gravity separating equipment, amalgamation equipment and so on, to improve the gold grade. Concentrating is an essential part in the alluvial gold mining method. Concentrating equipment should be paid attention to, to avoid the gold loss in concentrating. The recovery rate of gold and other heavy sand minerals is highly improved realizing comprehensive recycling and mineral resource utilization.

In actual production, the alluvial gold mining method and processing equipment should be determined according to the ore characteristics. The same method and equipment is not suitable for all the alluvial gold processing plant. Therefore, it is recommended to choose a qualified equipment manufacturer. Carrying out mineral processing experiment,

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE