Flotation is one of the commonly used methods for copper ore beneficiation. There are different types of copper ores in nature, and there are many kinds of copper ores that can be applied to flotation technology. The following will introduce you to the general process flow of copper ore flotation technology, the types of copper ore suitable for flotation technology and the equipment used in the flotation process.

Use the table of contents below to navigate through the guide:

01Copper flotation process technology

Copper ore flotation process is a method of separating and concentrating copper minerals and gangue minerals from ore. It relies on the difference in physical and chemical properties between copper minerals and gangue minerals.

The copper ore flotation process includes the following stages:

1. Crushing and grinding: the copper ore is sent to the crusher and grinding equipment to be processed into small particles. This step increases the specific surface area of the ore and helps expose the copper mineral to subsequent flotation.

2. Stirring and pulping: in the agitation equipment, the finely ground ore is mixed with water, medicine and foaming agent. Agents such as collectors, modifiers, and activators are added to enhance the desired attachment of copper minerals to air bubbles.

3. Foam flotation: Air foam is introduced into the flotation tank to form a foam layer on the surface. Hydrophobic copper minerals attach to the bubbles and rise to the top of the flotation cell to form froth, while hydrophilic gangue minerals remain in the slurry.

4. Concentration: Skim the froth containing copper minerals from the top of the flotation cell and collect it as a concentrate. Concentrates usually contain a higher percentage of copper and are further processed for smelting or refining.

5. Tailings treatment: The remaining slurry, called tailings, containing gangue minerals, is discharged from the flotation tank. Proper tailings disposal is a necessary measure to reduce environmental impact.

The success of the flotation process depends on a variety of factors, including ore mineralogy, particle size, pH, temperature, and the choice and dosage of reagents. Depending on the specific requirements of the operation, different types of flotation cells may be used, such as mechanical flotation cells or flotation columns. Overall, the flotation process is widely used in the beneficiation of copper ore and plays a key role in the copper mining industry to extract valuable copper minerals from complex deposits.

02Types of Copper Ore Suitable for Flotation

Below are some common copper ore types that can be processed through the flotation process:

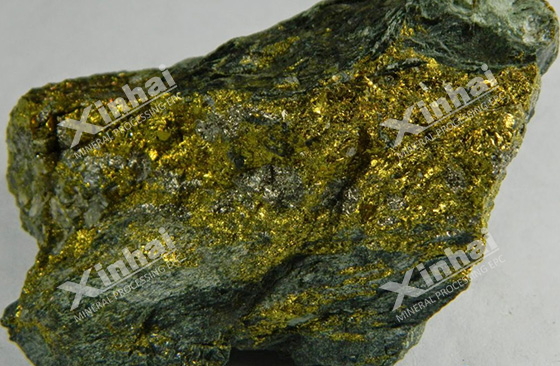

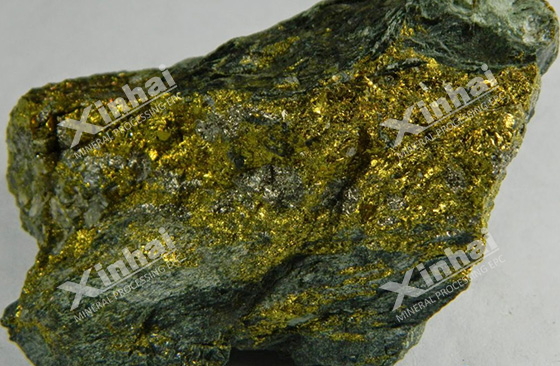

1. Chalcopyrite: Chalcopyrite is the most common copper mineral and the main source of copper. Copper minerals in chalcopyrite can be effectively separated from gangue by flotation.

2. Bornite: Bornite is a copper-iron sulfide mineral that can also be processed by flotation. It often occurs with chalcopyrite and other copper minerals.

3. Cobalt copper ore: Cobalt copper ore is a copper sulfide mineral that can be processed by flotation process. Cobaltite is relatively rare relative to chalcopyrite and bornite, but can still be found in some copper deposits.

4. Sulfurite: Sulphide is another copper sulfide mineral that can be processed by flotation. It often occurs in secondary copper deposits and is a valuable copper ore.

5. Tetrahedrite: Tetrahedrite is a complex copper-antimony sulfide mineral that can be processed by flotation. It contains large amounts of copper and is sometimes seen as copper ore.

6. Malachite and azurite: Although malachite and azurite are not sulfide minerals, they can still be processed by flotation in some cases. These minerals are commonly found in copper oxide deposits.

It is important to note that specific flotation conditions and reagent use may vary depending on ore characteristics, including mineralogy, particle size and the presence of other minerals. Each deposit may require a custom flotation process to achieve optimal copper recovery and concentrate grade.

Equipment used in each stage of copper ore flotation

At different stages of the copper ore flotation process, various machines and equipment can be used. The following machines are commonly used at each stage:

1. Crushing and grinding stage:

Jaw Crusher: Used to crush larger size copper ore into smaller particles.

Cone Crusher: Further reduces the size of copper ore particles.

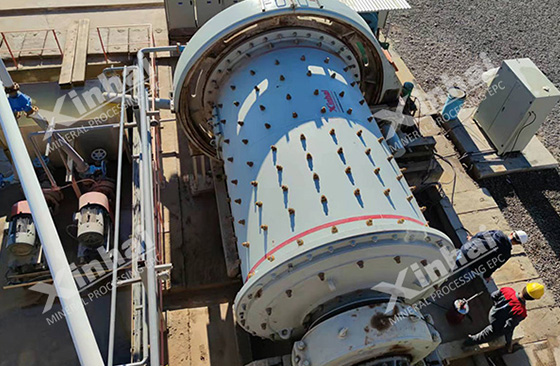

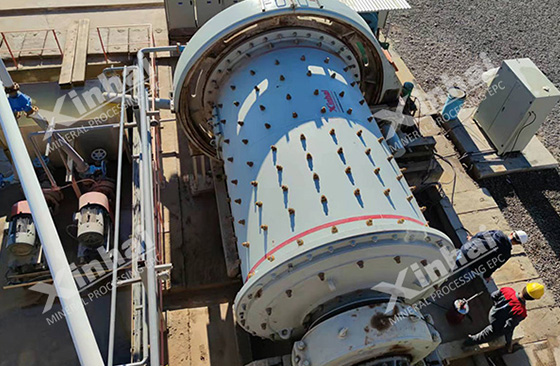

Ball Mill: Used to grind crushed copper ore into fine powder.

2. Stirring stage:

Stirring tank: the finely ground copper ore is mixed with water, chemicals and foaming agents to form a slurry. Common types include paddle agitators and impeller agitators.

3. Foam flotation stage:

Flotation tank: Provide the environment required for the flotation process and promote the attachment of air bubbles and copper minerals.

Flotation machine: specially designed to agitate the pulp and introduce air foam into the flotation cell.

4. Concentration stage:

Froth Drain: Collects the froth containing concentrated copper minerals and transfers it to the concentrate drain.

Concentrate Drain: Receives froth from the foam drain and allows copper concentrate to collect.

5. Tailings treatment stage:

Thickener: Remove excess water from tailings to form a thick slurry for disposal.

Filter press or filter: Separating the remaining water from the thick tailings to produce a dewatered tailings cake.

In addition, other auxiliary equipment such as pumps, piping, valves and monitoring instruments are available to control and optimize operations. The exact equipment used may vary depending on the size of the operation, ore characteristics and mining company preference. Depending on the specific requirements of the flotation process, flotation cells of different designs can also be used, such as mechanical flotation cells or flotation columns.

The above content is the copper ore flotation process, copper ore types and equipment suitable for copper ore flotation. In the flotation process, the equipment used is different, and the flotation process adopted by different ores is also different. Therefore, Xinhai Mining recommends to conduct a mineral processing test to determine the properties of the ore in order to determine the appropriate copper ore mineral processing plan and choose the right beneficiation equipment.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE