Ilmenite is a black or iron-black ore of two metallic elements, iron and titanium, which has many uses in industry. The beneficiation technology of ilmenite is mainly to separate the iron and titanium in the ore. Common ilmenite ore beneficiation technologies include: magnetic separation, gravity separation, flotation, magnetic-gravity combined separation, high-intensity magnetic separation, etc. This article will mainly introduce you to the beneficiation method of ilmenite from the above five aspects.

Use the table of contents below to navigate through the guide:

01Ilmenite magnetic separation technology

The magnetite in ilmenite often contains high iron content, and magnetic separation technology can be used to separate these magnetites. During magnetic separation, magnetite is attracted by the magnetic field and collected, and moves along the direction of the magnetic field. Therefore, the separation of magnetic minerals can be controlled by adjusting the strength and direction of the magnetic field. Ilmenite is a non-magnetic mineral and is not affected by magnetic fields and remains in place. Magnetic separation can effectively separate magnetic minerals from non-magnetic minerals and achieve the separation of iron and titanium. Magnetic separation technology can reduce mineral processing costs, produce high-grade concentrates, and meet the requirements of different applications.

02Ilmenite gravity separation technology

Gravity separation technology mainly uses the density difference between different minerals for sorting. The titanium ore in ilmenite is dense and can be separated using gravity separation technology. During gravity separation process, equipment such as shakers and jigs can be used to separate minerals of different densities into layers.

Before gravity separation, the ilmenite is crushed and ground into appropriate particle size, and then put into the gravity separation equipment for separation. During the sorting process, other minerals precipitate and float. During gravity separation, equipment parameters, such as inclination angle, speed, etc., can be appropriately adjusted to improve sorting efficiency. Ilmenite gravity separation technology can separate iron and titanium without adding chemicals, reducing costs while improving product quality.

03Ilmenite ore flotation technology

Different minerals in ilmenite have different adsorption properties under the action of bubbles, and the separation of iron and titanium can be achieved through buoyancy. Flotation technology can be used to separate certain non-magnetic minerals containing titanium from ores. The pretreated ilmenite is transported to the flotation machine, and specific flotation chemicals are added to the flotation equipment. These agents can create affinity between specific mineral particles and bubbles, causing them to adhere to the surface of the bubbles and float up, forming a foam layer. At the same time, other mineral particles sink. By adjusting parameters such as flotation agent type, concentration, and bubble size and distribution, effective separation of different minerals such as iron and titanium can be achieved. This method can achieve selective separation of minerals in water and provide a basis for enriching minerals in subsequent processing steps.

04Ilmenite magnetic-gravity combined mineral processing technology

This technology combines magnetic separation and gravity separation to achieve effective separation of titanium and iron. Ilmenite is first separated by magnetic separation, using magnetism to separate magnetic minerals such as magnetite. The separated magnetic minerals are gravity separated to separate out the non-magnetic mineral ilmenite. The combination of these two separation technologies can improve the efficiency of separation of iron and titanium minerals and improve the quality of the product. It is an efficient iron-titanium ore separation technology.

High-intensity magnetic separation technology for iron-titanium ore

High-intensity magnetic separation technology is a special magnetic separation technology that uses the principle of magnetic separation under high magnetic field intensity to achieve efficient separation of minerals such as iron and titanium. In this technology, by using a high-intensity magnetic field, the difference between the magnetic mineral magnetite and the non-magnetic mineral ilmenite can be enhanced, thereby achieving more effective separation of minerals. Under the influence of high magnetic field strength, magnetic minerals will experience stronger magnetic attraction, making them easier to separate. By adjusting the strength and direction of the magnetic field, the separation effect of different minerals can be controlled, resulting in purer iron and titanium products. High-intensity magnetic separation technology can improve mineral processing efficiency, reduce costs, and is suitable for processing iron-titanium ore containing higher magnetic minerals.

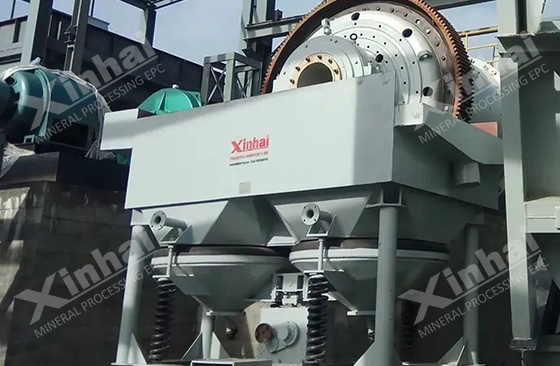

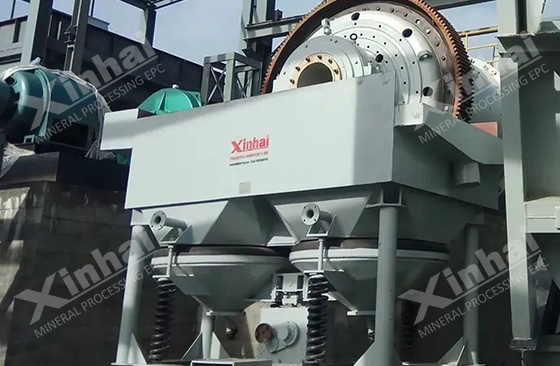

The above are the five ore beneficiation technologies for ilmenite. In the actual beneficiation process, the specific beneficiation methods may be adjusted and combined based on factors such as the characteristics of the ore, target product quality requirements, and engineering economic considerations. Xinhai Mining recommends conducting ore beneficiation test analysis to determine the characteristics of the ore. Customized design of the process according to the characteristics of the ore can improve the separation efficiency and concentrate taste while reducing production costs and improving economic benefits.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE