Iron sphalerite is one of the main zinc ores, usually in yellow, brown, black, etc., and is a brittle mineral with a hardness between 3.5-4. As one of the main sources of zinc, sphalerite is widely distributed in the earth's crust, often accompanied by other sulfide minerals such as pyrite and chalcopyrite. Zinc is used industrially for galvanizing, alloy preparation, battery production, chemical raw materials, etc. As an important zinc ore, zinc metal can be obtained through flotation extraction and separation of concentrates or used in the production of zinc compounds. The following will introduce the flotation technology of sphalerite from three aspects: the flotation process of sphalerite, flotation reagents and technical difficulties.

Use the table of contents below to navigate through the guide:

01Flotation process of iron sphalerite

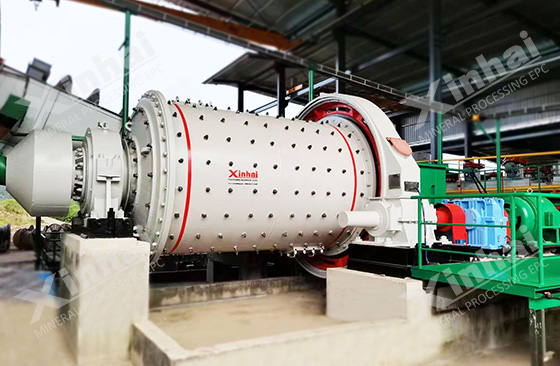

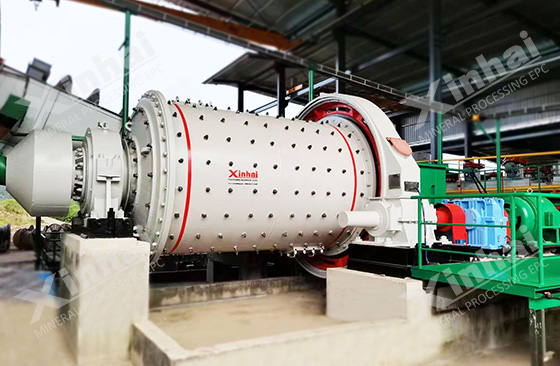

Iron sphalerite flotation technology is a technology widely used in the separation and extraction of zinc ore. First, the raw ore enters the crushing equipment, screening equipment and grinding equipment for processing. After the ore reaches the appropriate particle size, it enters flotation. Then, flotation chemicals are added into the flotation machine. After these chemicals are fully mixed with the slurry, they interact with the surface of the sphalerite and reduce its hydrophilicity. Next, mechanical stirring and ventilation are used to generate bubbles. The sphalerite particles will adhere to these bubbles and rise to the liquid surface to become flotation foam, while impurity minerals will settle to the bottom. The foam product is then scraped and further processed to obtain a higher grade zinc concentrate. The flotated minerals need to undergo concentration, washing and drying steps for further extraction of zinc concentrate.

During the flotation process, flotation reagents, stirring intensity, gas input volume and time, and subsequent concentrate processing should be strictly controlled to achieve effective separation and extraction of sphalerite.

02Flotation reagents for iron sphalerite

The flotation reagents for iron sphalerite mainly include flotation agents and regulators. Flotation agent is used to change the interaction between ore and bubbles to achieve the effect of zinc mineral separation. Commonly used flotation agents include xanthate, fatty alcohol, etc. Xanthate is often used as a flotation agent for zinc sulfide ores. They can be adsorbed on the surface of zinc minerals and form bubbles, thereby causing the minerals to float. Adjusters are generally used to control the pH value of the ore slurry, mainly affecting the chemical reaction between the ore and the flotation machine. Under alkaline conditions, the flotation effect of sphalerite is good, so alkaline substances such as lime or sodium hydroxide are generally used as flotation regulators for sphalerite.

The selection and proportion of mineral processing reagents should be determined according to the specific ore properties and mineral processing technology, so as to achieve good flotation effects.

03Technical difficulties in iron sphalerite flotation

As a commonly used mineral processing technology, there are also technical difficulties in the iron sphalerite flotation process.

1. Ore complexity: Iron sphalerite ore often coexists with other sulfide minerals, such as pyrite and chalcopyrite, which leads to an increase in the complexity of the ore during its flotation process and an increase in the difficulty of separation between minerals.

2. Reagent selection and adjustment: For the flotation process, the selection of reagents is very important. However, due to the different properties of different ores, the chemical combination and additive dosage need to be adjusted according to the properties of the ores, especially when dealing with polymetallic ores.

3. Ore particle characteristics: The size, shape and surface properties of sphalerite particles will affect the adhesion of bubbles and flotation effect, so the particle size distribution and surface properties of the ore need to be optimized.

4. Bubble generation and control: When flotating iron sphalerite, generating stable bubbles and attaching them to the ore particles is a key step. Therefore, achieving effective bubble generation and control under different circumstances is a technical difficulty in the flotation process.

5. Subsequent processing and concentration: The flotation concentrate product also needs to complete separation and concentration steps to obtain higher-grade zinc ore concentrate products. However, it is difficult to separate different minerals and complete subsequent processing during the flotation process of polymetallic ores. Therefore, process optimization needs to be carried out based on actual production conditions.

6. Environmental impact: The flotation process requires a large amount of water and chemicals, so the treatment of wastewater and chemical substances generated during the process is a major difficulty. In order to reduce the negative impact on the environment, process adjustments are required.

The above is the flotation process, reagents and some technical difficulties of iron sphalerite. The specific flotation process formulation, chemical selection and ratio should be adjusted according to the characteristics of the ore and production needs. The mineral processing process will encounter various conditions. In order to improve the mineral processing efficiency, an appropriate flotation process and corresponding equipment should be formulated based on the ore beneficiation test results to improve the concentrate grade and mineral processing production efficiency.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE