Because of special geological conditions, Mexico is with rich mineral resources. However, local mining development technology is limited, resulting in mining development is still in its primary stage. To improve the supply capacity of mineral resources, Mexico has customized the going-out development strategy of mineral resources. Over the years, Xinhai has been continuously developing the Mexican mining market, bringing advanced beneficiation technology and innovative beneficiation equipment to Mexico, and improving the level of local beneficiation technology. In 2022, Mexico 1200tpd gold cyanide processing plant project undertaken by Xinhai Mining will be put into production, and Xinhai Mining has also taken a new step in the Mexican market.

Use the table of contents below to navigate through the guide:

01Project Background

This project is the re-cooperation between Xinhai and the customer. In 2017, Xinhai Mining undertook the customer's 1500tpd copper-lead-zinc-gold-silver polymetallic ore project in Mexico. Since the project cooperation was very pleasant, and the overall project design plan met expectations. Therefore, the client of this project chose to cooperate with Xinhai again in the preparatory stage of the new project to help it complete the construction of the 1200tpd gold mine cyanide processing plant.

02Project Overview

♦ Ore properties: The raw ore processed in this project is the tailings of the original flotation plant

♦ Processing capacity: 1200tpd

♦ Process flow: all-slime cyanidation gold extraction process

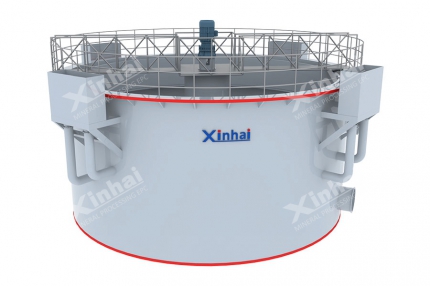

♦ Main equipment: flotation machine, ball mill, analysis tank, acid leaching tank, liquid storage tank, adsorption column, thickener, hydrocyclone, submerged pump, linear vibrating screen, vacuum filter, etc.

03Xinhai Solution

According to the contract signed by both parties, the design of project mainly includes: cyanide leaching system, pharmaceutical preparation system, desorption electrolysis system, smelting system, etc.

When designing the solution, Xinhai fully considers the actual geography, geology, landform and climate conditions of the concentrator construction site. At the same time, Xinhai takes energy saving, consumption reduction, comprehensive utilization, low investment, short construction period and quick effect into account. In this way, the mineral processing project can be long-term, safe, stable and continuous operation to produce qualified products. The specific process flow is as follows:

1. Cyanide leaching system:

The raw ore flotation tailings slurry is pumped to the thickener before leaching, concentrated to a concentration of 40%, and then enters the cyanide leaching system for leaching and adsorption operation to obtain qualified gold-loaded carbon.

2. Desorption electrolysis system:

The qualified gold-loaded carbon is sent to the desorption electrolysis system. Under the action of high temperature and high pressure, anions that are easily adsorbed by activated carbon are added to the desorption system to replace Au(CN)2-.

3. Smelting system:

After pickling and impurity removal, gold mud can be obtained, which can be directly smelted to obtain gold ingots.

After the design, Xinhai immediately started the production and procurement of the mineral processing equipment and accessories, and sent the equipment to the project site through a strict and standardized packaging and shipping process.

04Project Highlights

Xinhai carries out the process design of the project according to the actual situation in combination with the local topography and local policy.

In order complete the project and put into operation as soon as possible, Xinhai works overtime during the limited construction period to produce and deliver equipment. We also overcome the difficulties during the epidemic, and complete the arduous project production tasks in advance at a relatively fast speed while ensuring quality. It can promote the project process effectively.

The cooperation with this mining company in Mexico has further consolidated the development of Xinhai mining machinery in Mexico. As the proposer and practitioner of "Mining Whole Industry Chain Service (EPC+M+O)", Xinhai is driven by technological innovation to create tailor-made mineral processing solutions and high-quality and considerate mineral processing equipment. In the future, Xinhai will continue to provide global customers with more complete, professional and in-place mining industry chain services (EPC+M+O)!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE