With the advancement of science and technology, digitalization,

intelligentization, and other innovations are increasingly being applied in

modern copper ore dressing plants. The traditional subcontracting model can

hardly meet the needs of modern mining enterprises. The EPC+M+O (Engineering,

Procurement, Construction Management + Operation) general contracting model

offers a comprehensive solution for the construction and operation of copper ore

dressing plants, making it a preferred choice for mining companies.

Use the table of contents below to navigate through the guide:

01What is the EPC+M+O model of copper ore Dressing Projects?

The EPC+M+O model is a mining industry chain management model that integrates

engineering, procurement, construction management and operation. The

characteristic of this model is that it manages all stages of the project in a

unified manner, achieving seamless connection from project planning to

operation. After years of project practice, the application of this model in the

mining field has gradually matured, especially in the construction and operation

of copper ore dressing plants, showing many advantages.

02Advantages of the EPC+M+O Model in Copper Ore Processing

1. Project Management Advantages

The core purpose of the EPC+M+O model is to have a general contractor

responsible for the full-process management of the project. This approach

eliminates the need for multi-party coordination seen in traditional models and

prevents issues such as buck-passing and disputes. Under the EPC+M+O model,

responsibilities within the copper ore dressing plant are clearly defined,

ensuring the efficient operation of all stages.

2. Cost Control Advantage

Compared with the traditional subcontracting model, the EPC+M+O model reduces

intermediate steps through one-stop services, thereby effectively lowering

project costs. The general contractor can optimize the process flow and select

more cost-effective equipment and materials during the design phase. In

addition, centralized procurement and optimized supply chain management allow

the general contractor to further reduce procurement expenses.

The EPC+M+O model also minimizes the impact of project risks on costs through

a risk-sharing mechanism. For example, the general contractor may adopt

fixed-price contracts to ensure cost stability for the owner and avoid budget

overruns caused by market price fluctuations or construction delays.

3. Technical and Quality Advantages

The advantages of the EPC+M+O model are not only reflected in project

management and cost control, but also in technological innovation and quality

assurance. The general contractor typically has a professional technical team

with expertise across multiple areas, including mineral processing design,

equipment R&D and procurement, engineering construction, and operational

management. By integrating cutting-edge technologies, the general contractor can

offer customers advanced mineral processing solutions and optimal equipment

selection.

4. Operational Advantages

Another significant advantage of the EPC+M+O model lies in its effectiveness

during the operational stage. The general contractor becomes involved in

operational planning early in the project construction process, ensuring a

seamless transition from construction to operation.

The general contractor's operations team typically possesses extensive

industry experience and can enhance the efficiency of the mineral processing

plant through optimized production processes, equipment maintenance, and

personnel management. For instance, with the help of intelligent equipment

management systems, the operations team can monitor equipment performance in

real time, detect potential failures in advance, and minimize downtime.

03Cases of the EPC+M+O Model in Copper Ore Processing

1. Myanmar 500t/d Copper Processing Case

The Myanmar 500t/d copper processing case is a full-industry-chain service

project provided by Xinhai Mining. The services mainly include beneficiation

testing, process design, equipment manufacturing, packaging and shipping,

installation and commissioning, and employee training.

Based on test results, Xinhai adopted a closed-circuit process of crushing,

grinding and classification, followed by one-stage roughing, two-stage cleaning,

and three-stage scavenging flotation.

The project adopted the EPC+M+O model, which shortened the project cycle,

reduced investment costs during plant construction, and improved the

beneficiation recovery rate — truly achieving the effect of "killing two birds

with one stone."

2. Pakistan 1500t/d Copper Processing Case

A large copper ore dressing plant in Pakistan adopted the EPC+M+O general

contracting model for both construction and operation. Xinhai selected a

flotation process consisting of one-stage roughing, two-stage scavenging, and

two-stage cleaning through optimized design.

Xinhai provided services including equipment manufacturing, procurement, and

installation. Through centralized procurement and optimized supply chain

management, the company reduced equipment procurement costs for the client.

During the construction phase, Xinhai maintained strict quality control to

ensure on-time project delivery. In the operation phase, Xinhai improved mineral

processing efficiency by optimizing the production process through an

intelligent management system.

04Features and strengths of Xinhai EPC+M+O model

1. Professional Team and Technical Strength

As a manufacturer specializing in mineral processing technology and

equipment, Xinhai has a professional technical team with expertise in various

areas, including mineral processing design, equipment R&D and procurement,

engineering construction, and operation management.

Xinhai’s technical personnel possess extensive industry experience and can

provide customers with comprehensive services ranging from project planning to

operation. In addition, we hold several core technology patents that enable us

to offer advanced mineral processing technologies and equipment solutions.

2. Extensive Project Experience and Successful Cases

Xinhai has extensive experience in EPC+M+O projects and has successfully

completed multiple copper ore dressing plant projects, such as the Myanmar

copper mine project and the Pakistan copper mine project mentioned above.

Whether in domestic or international markets, we have earned high praise from

clients through our professional expertise and services. Our projects span

dressing plants of various scales and geological conditions, fully demonstrating

our capability to execute projects in complex environments.

3. Robust Management System and Quality Assurance

Xinhai has established a comprehensive quality management system, project

management system, and safety assurance system. During project implementation,

we strictly control the quality of every stage to ensure on-time delivery and

compliance with design specifications.

Meanwhile, we prioritize safety management. Through a well-established safety

assurance system, we ensure the safety of personnel and equipment throughout

both the construction and operational phases.

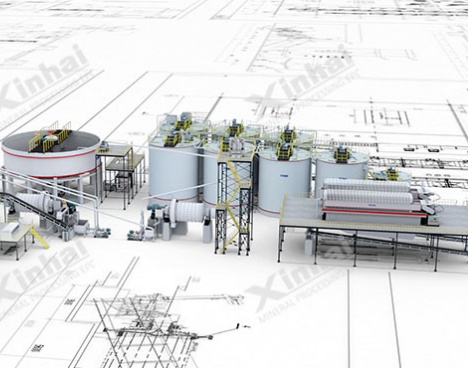

4. Digital and Intelligent Concentrator

With the continuous development of the mining industry, Xinhai has gradually

integrated digital and intelligent technologies to further enhance the

advantages of the EPC+M+O model.

For example, by adopting big data analytics and artificial intelligence

technologies, we optimize mineral processing workflows and equipment management,

thereby improving the overall intelligence level of concentrators.

Xinhai remains committed to delivering high-quality services and creating

greater value for customers through ongoing innovation and service upgrades.

Conclusion

Through the practical application of multiple projects, it is evident that

the EPC+M+O general contracting model offers significant advantages over the

traditional subcontracting approach in areas such as project management, cost

control, operational efficiency, and quality assurance.

It is a high-quality solution for modern copper ore concentrators. Xinhai

provides end-to-end services from project planning to operation and is capable

of delivering efficient, cost-effective, and stable copper ore dressing plants

for its clients.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE