Recently, the Zimbabwe 2 Million TPA Spodumene Ore Processing Project undertaken by Xinhai Mining has successfully entered the stage of trial production, which took only one year. Xinhai Mining signed a contract with Sinomine Resources in June 2022. This project is the "Turn-key Service for Mineral Processing Plant (EPC+M+O)" project undertaken by Xinhai Mining, providing research and design, and complete equipment manufacturing and procurement, commissioning and delivery, mine management and operation and other services. In September 2022, Xinhai Mining determined the beneficiation plan based on the test results. The following will introduce the spodumene ore beneficiation process of this project.

Use the table of contents below to navigate through the guide:

01Spodumene ore coarse, intermediate and fine crushing process

The crushing and grinding process is the key technology of the concentrator, which greatly affects the infrastructure investment, production stability and production cost to a large extent. In line with the principle of "more crushing and less grinding, energy saving and consumption reduction", Xinhai Mining adopts three-stage and one-closed circuit crushing process. The raw ore first enters the jaw crusher through the feeder, and then enter the two cone crushers to crush the raw ore to meet the particle size of the grinding requirements.

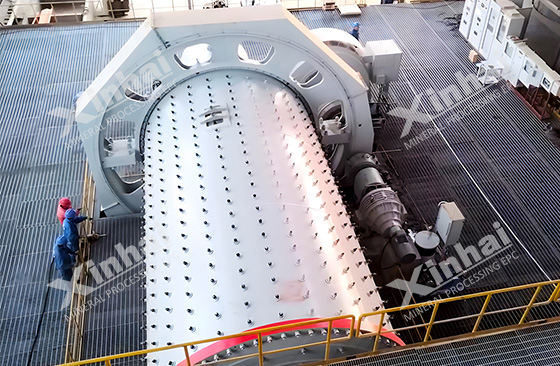

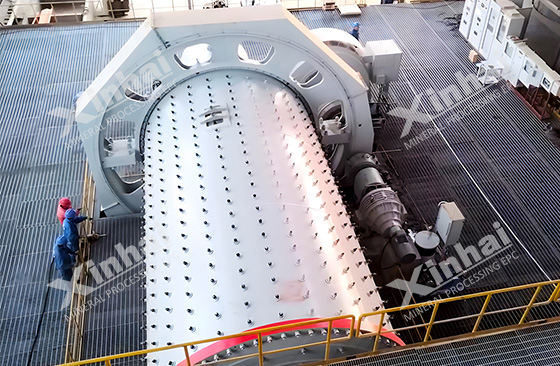

02Spodumene ore grinding and classifying process

To improve the working efficiency of grinding equipment, crushed products should be sent into the screening machine for screening before into ball mill machine. The products under the screen can enter the ball mill for grinding process. The product on the screen need to back to the crushing process for re-processing, forming a closed-circuit with above crushing process. This process can avoid over grinding and ensure the grinding efficiency of machine. Xinhai Mining adopts “one-stage grinding and one-stage classifying” process. The under-screen products will enter wet grid type ball mill for grinding process and hydrocyclone for classifying.

03Spodumene ore magnetic separation and desliming process

This process is to remove the impurities. Xinhai Mining adopts “one-stage magnetic separation process and two-stage desliming process”. The spodumene ore is a kind of weak magnetic mineral, classified products enter magnetic drum for magnetic separation and desimling cyclone for desimling. The bottom flow from cyclone will flow into flotation system for processing.

04Spodumene ore flotation process

The spodumene flotation first adopts one-stage reverse flotation to remove some impurities in the pulp, and then adopts the "one-stage roughing, three-stage scavenging and three-concentrating" process of direct flotation. This flotation process is designed in combination with beneficiation test results and customer needs, which can improve the grade and recovery rate of spodumene concentrate. The selection of the flotation process will change with the characteristics of the ore, and the results of the mineral processing test are an important basis for the design of the overall mineral processing process.

05Spodumene ore concentration and dehydration+tailings treatment process

After flotation, the spodumene concentrate needs to be dehydrated using a two-stage process of "thickener + filter press". The flotation concentrate is pumped into the hydraulic central transmission high-efficiency thickener by the slurry pump for concentration. The underflow of the thickener is pumped into the chamber filter press for dehydration. The dehydrated concentrate can be transported to the concentrate storage. The tailings generated in each operation need to enter the thickener for concentration and dehydration. The overflow part of the thickener flows to the return pool for recycling, and the bottom flow is transported to the tailings pond for storage.

The above is a brief introduction to the process flow of the 2 million TPA spodumene ore processing plant in Zimbabwe. Xinhai Mining provides tailor-made whole industry chain services for this project. A professional team is in charge of each link of the project construction, and a strict construction progress plan has been formulated. With the joint efforts of all departments of Xinhai Mining, it took one year for the project to be put into trial operation successfully, demonstrating Xinhai's speed. In the past 30 years, Xinhai Mining's service has covered 95 countries around the world, and has undertaken more than 500 mine EPC projects. The success of this project has once again proved the ability and strength of Xinhai Mining through practice!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE