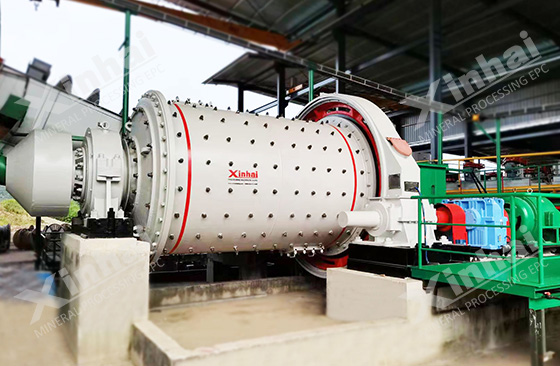

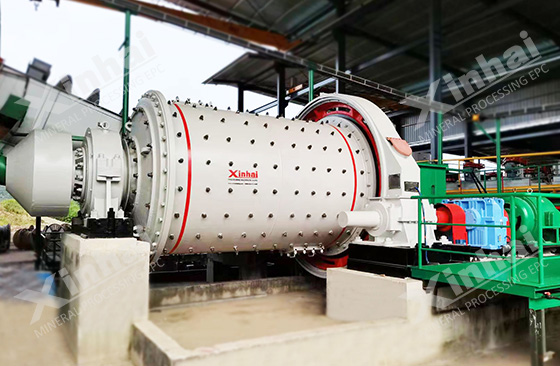

In iron ore mineral beneficiation, the grinding process is one of the important process in iron ore processing. As one of the commonly used grinding equipment, ball mill plays a key role in iron ore beneficiation. This article will introduce 3 types of ball mills and their application in iron ore processing, aiming to help optimize the iron ore beneficiation process and improve ore utilization and production efficiency.

Use the table of contents below to navigate through the guide:

01The working principle of ball mill

The ball mill is equipped with steel balls in the rotating cylinder, and the ore and steel balls are rotated together to realize the crushing, grinding and mixing of ore. The steel ball collides, rubs and wears with the ore during the rotation, so as to crush the ore into the required particle size. During the grinding process, the working effect of the ball mill will be affected by many factors, such as the size and type of the steel ball, the filling rate of the grinding medium, the rotation speed, etc. Therefore, in actual production, the concentrator should select the appropriate grinding medium, adjust the filling rate of the medium and the rotating speed of the cylinder according to the characteristics of the ore itself.

02Three common iron ore mineral ball mills

(1)Overflow ball mill

Overflow ball mill is one of the more common types of ball mills. Its working principle is: through the overflow device at both ends of the cylinder, the ore and grinding medium are added from one end of the cylinder during the rotation process and overflow from the other end. The overflow ball millis suitable for the treatment of medium and coarse grinding minerals, with simple structure, convenient operation and high grinding efficiency.

(2)Grid type ball mill

The structure of the grid type ball mill is quite different from that of the overflow type ball mill. A series of grid plates are set in the cylinder of the grid type ball mill for classifying and screening grinding media and ores. The grid type ball mill is suitable for the treatment of relatively finely ground minerals. By controlling the size and shape of the grid plate, the particle size classification and separation of the grinding medium and ore can be realized.

(3)Dry ball mill

It is a ball mill equipment for processing dry materials. Its working process is as follows: the material enters the first chamber of the mill evenly, and the steel balls in the chamber fall down after reaching a certain height when the cylinder rotates, causing heavy impact and grinding on the material. After rough grinding, the material will enter the second bin, which is filled with steel balls, which can further grind the material, and the powder is discharged through the discharge plate to complete the grinding operation. There are two types of dry ball mills, wet type and dry type, and the selection can be made according to the material and ore discharge method.

03Application of ball mill in iron ore mineral beneficiation process

Ball mills are widely used in iron ore processing. It can not only be used for the pretreatment of the grinding link, but also crush the ore into the required particle size, and provide suitable ore powder for the subsequent sorting, flotation and magnetic separation. It can also be used in fine grinding to improve the fineness and grade of iron concentrate. In the iron ore beneficiation process, different types of ball mills can choose the appropriate model and configuration according to the ore characteristics, process requirements and production scale.

As an indispensable grinding equipment in iron ore mineral beneficiation, ball mill has many types and applications. Choosing the right type of ball mill is crucial to optimizing the iron ore processing process, increasing ore utilization and production efficiency. In practical application, according to the comprehensive consideration of ore characteristics, process requirements, production scale and other factors, selecting the appropriate type of ball mill, and performing corresponding operations and adjustments can effectively improve the effect and economic benefits of iron mineral beneficiation. Therefore, Xinhai Mining recommends that before purchasing a ball mill, an ore beneficiation experiment analysis should be carried out to determine the suitable type of ball mill, which can save costs and improve the utilization rate of iron ore resources.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE

.jpg)