In conventional mining project development, fragmented workflows—spanning investment, engineering, equipment supply, construction, and operation—often result in misaligned responsibilities and inefficient coordination. These challenges frequently lead to cost overruns, schedule delays, and post-commissioning modifications, issues commonly encountered across mining projects worldwide.

Against the backdrop of the industry’s transition toward higher-quality, greener, and more intelligent development, the China Collaborative Innovation Platform for Mineral Resources and Materials Application convened the Integrated Mining Solutions Seminar on December 22, 2025, in Yantai, Shandong. The seminar focused on how full industry chain collaboration can support more efficient and sustainable mining project delivery.

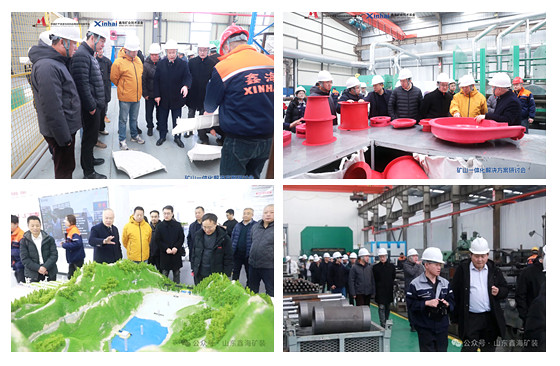

(On-site discussion at the Integrated Mining Solutions Seminar)

Use the table of contents below to navigate through the guide:

01Industry Dialogue on Lifecycle-Oriented Mining Development

Hosted at the Academic Exchange Center of Shandong Xinhai Mining Technology & Equipment Inc., the event brought together representatives from mining associations, mining companies, universities, investment institutions, geological survey organizations, and research institutes. Discussions centered on mine lifecycle management, the practical application of the EPC+M+O model, and mechanisms for improving coordination across investment, construction, and operation stages.

As the host, Xinhai provided a professional platform for open dialogue while sharing its experience in delivering integrated mining solutions across diverse project conditions.

With more than 30 years of industry experience, Xinhai specializes in end-to-end mining services and holds a Class-A qualification in mining engineering construction. The company has participated in over 2,500 mining projects covering more than 70 mineral types, including gold, silver, copper, iron, lithium, and manganese. To date, Xinhai has delivered over 600 EPC+M+O projects in more than 100 countries, building a strong track record in complex, multi-disciplinary mining project execution.

02Advancing Integrated Mining Solutions Through EPC+M+O

During the seminar, participants engaged in in-depth discussions on mining investment strategy, processing technology, engineering management, and operational integration, examining how different stakeholders can contribute to more cohesive and resilient project delivery models.

(Industry exchange session at the Integrated Mining Solutions Seminar)

Mr. Zhang Yunlong, Chairman of Xinhai, delivered a keynote presentation titled “Enhancing Mining Economics Through Mineral Processing Technology and the EPC+M+O Model.” He outlined how integrated EPC+M+O services can reduce investment risk, shorten construction timelines, improve commissioning efficiency, and support stable long-term operations. His presentation addressed key aspects of project execution, including due diligence, representative sampling for mineral processing tests, comprehensive investment estimation, process technology optimization, and the development of green and intelligent mines.

(Zhang Yunlong, Chairman of Xinhai Mining, delivering a keynote presentation)

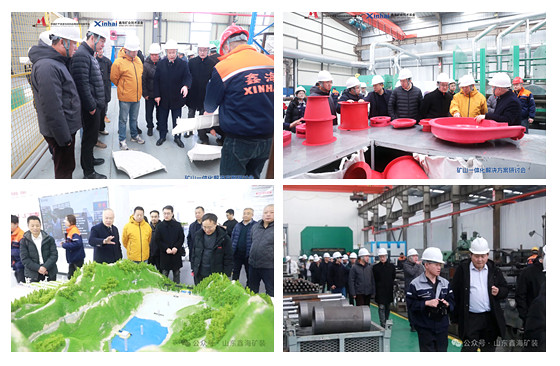

Following the seminar, participants visited Xinhai’s headquarters and Smart Equipment Industrial Park. Through site tours and technical briefings, attendees gained further insight into Xinhai’s intelligent manufacturing capabilities, core technologies, and integrated service framework.

(Chairman Zhang Yunlong accompanying guests on a visit to Xinhai Mining)

03Xinhai’s Integrated Mine EPC+M+O Service Model

Building on decades of engineering and project experience, Xinhai has developed an integrated EPC+M+O service system covering the full mine lifecycle, enabling coordinated, systematic, and complete project delivery.

E – Mine Technical Consulting & Test Research

Xinhai conducts systematic mineral processing tests and ore characterization to develop tailored process flowsheets that optimize both recovery performance and project economics.

P – Equipment Manufacturing & Procurement

Through its “1+3” operating model—one headquarters supported by three specialized manufacturing bases—Xinhai independently develops core equipment while selecting auxiliary components based on process requirements, ensuring strong alignment between equipment performance and flowsheet design.

C – Construction, Installation, Commissioning & Handover

With a Class-A qualification in mining engineering construction and over 20 years of site experience, Xinhai coordinates mining, processing, and tailings facility construction to avoid schedule imbalances. Installation and commissioning are executed by in-house teams, reducing trial-run periods and supporting timely, compliant project handover.

M – Mine Construction Management

Xinhai provides full-process EPC project management, covering design, manufacturing, procurement, construction, installation, commissioning, and trial operation, with integrated control of schedule, quality, cost, and safety.

O – Mine Operation Management & Services

Flexible cooperation models are offered, including turnkey operation, subcontract management, and joint operation. Xinhai also supports the optimization of existing operating teams, helping clients continuously improve efficiency and maintain stable production.

04Looking Ahead

The seminar facilitated constructive industry exchange and reflected growing recognition of integrated mining service models. Going forward, Xinhai will continue to advance its EPC+M+O framework through technological innovation and management optimization, supporting safer, more efficient, and more sustainable

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE