In almost every gold project I’ve worked on, the story starts the same way: someone brings a rock and asks, “Is this gold?”

Knowing how to recognize gold ore correctly is not just a curiosity question. For investors, miners and project owners, it is the first risk-control step in the whole value chain—from sampling and drilling, to process design, equipment selection and final plant performance.

Below, I’ll share, from a working miner’s perspective, how we recognize gold ore rock in the field and in the lab, where people usually go wrong, and how professional gold ore testing links directly to successful project development.

Use the table of contents below to navigate through the guide:

01Basic Principles of Gold Ore Rock Identification

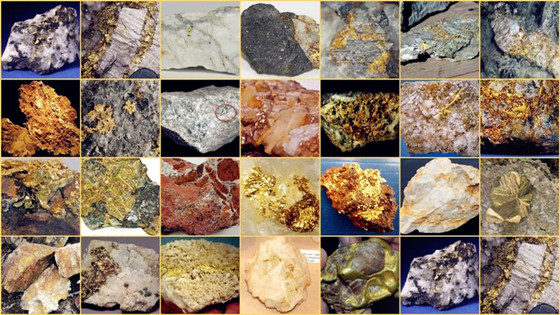

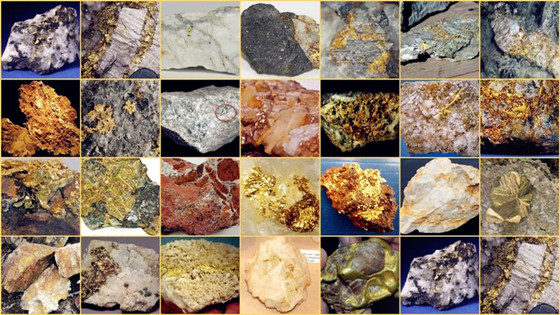

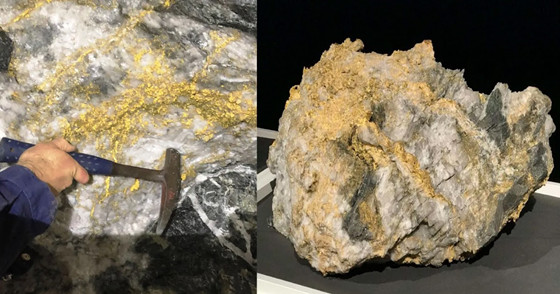

Before delving into exploration techniques, let’s first understand the true form of gold ore. Gold ore is the host rock matrix in which gold particles are embedded, typically found in quartz veins or sulfide matrices. Gold does not exist in isolation; it is influenced by geological processes such as hydrothermal activity or erosion, forming deposits that vary in colour, texture, and composition.

Understanding the context of the mineral site is a crucial first step. Due to variations in formation processes and environments, there are numerous types of gold deposits. Common types include: epithermal deposits, orogenic gold deposits, Carlin-type deposits, porphyry deposits, iron oxide copper-gold deposits, black shale-hosted deposits, and sandstone-type deposits.

If your area has a known history of volcanic activity, you may encounter epithermal deposits containing fine-grained gold mineralisation. In sedimentary basins, Carlin-type ores may appear in the form of invisible gold in carbonate rocks. Mastering these fundamentals can help narrow down the possibilities and determine whether that shiny rock is worth exploring, thereby saving you time and resources on unpromising prospects.

02Key Methods to Recognize Gold Ore: From Field Observation to Lab Testing

Identifying gold ore requires a combination of field experience and scientific verification. Below are the most reliable methods used in practical mining operations, ranked by ease of use and practicality.

Visual inspection of gold ore rock

When I examine a piece of gold ore rock in the field, I usually follow this sequence:

1. Check structure and context

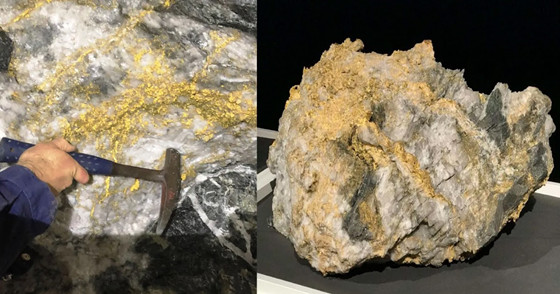

Veins cutting through host rock, especially quartz or quartz-carbonate

Shear zones, breccias, stockworks

Proximity to known mineralized trends or alteration zones

2. Look for alteration and iron staining

Strong limonite, goethite, hematite halos

Silicification, argillic or sericitic alteration

These often indicate previous sulfide mineralization where gold may be present.

3. Search for visible gold or sulfides

Coarse visible gold is obvious but not common

Pyrite, arsenopyrite and other sulfides can signal gold, especially in orogenic and Carlin-type deposits

Visual inspection won’t give you a grade, but it helps you decide whether the rock is worth more detailed gold ore testing.

☞Explore the 4 key methods for oxidized gold ore extraction — start optimizing your gold recovery now!

Simple physical tests for raw gold ore

With a basic field kit, you can run several useful checks:

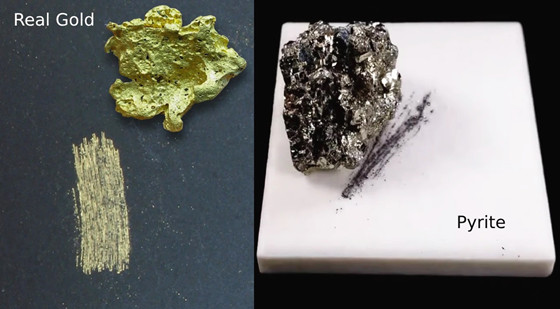

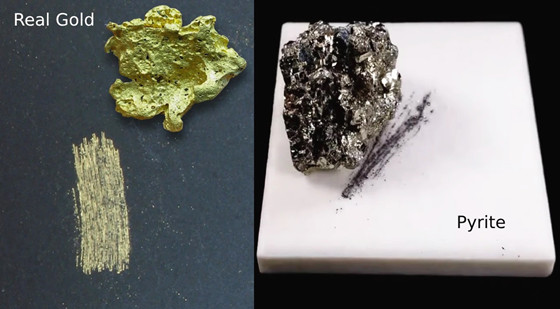

1. Streak test

2. Hardness test

Use a knife or steel nail.

If the yellow metal scratches easily, it may be gold.

If it scratches the knife, it is too hard to be gold.

3. Malleability test

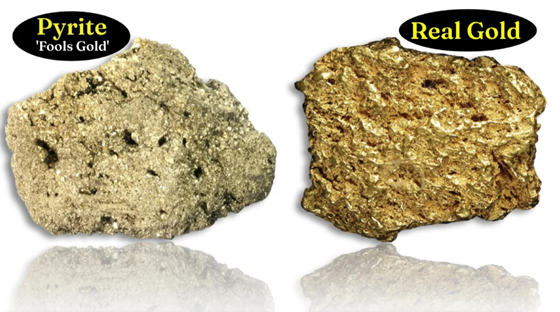

Gently tap the suspected gold with a hammer.

Gold: flattens into a thin plate.

Pyrite: breaks or powders.

4. Panning / gravity check

Basic tools for testing gold ore rock

For field identification of raw gold ore, a small, realistic kit includes:

These tools will not replace a laboratory, but they help you identify gold ore that is worth sending for professional testing.

Laboratory Testing: When You Need Professional Gold Ore Evaluation

In addition to the above methods, you can also hire an assayist to send your mineral samples to a laboratory for analysis. The analyst can examine the full metallurgical composition of the rock, yielding more precise and detailed results.

1. Assay and chemical analysis

Typical tests include:

Fire assay for gold and silver – Still the industry standard for accurate grade.

Atomic absorption (AAS) or ICP-MS – For multi-element suites (As, Cu, Pb, Zn, etc.).

XRF – Fast screening of major and minor elements.

These tests tell you how much gold is in the raw ore, and which associated elements may affect processing (e.g. arsenic, copper, sulfur).

2. Mineral processing testwork

From an engineering perspective, identification is incomplete without understanding how the gold behaves in processing:

Gravity tests – Is gold recoverable by shaking table, jig, or centrifugal concentrator?

Cyanidation bottle roll / column tests – Is the ore amenable to heap leach or CIL/CIP?

Flotation tests – For sulfide-hosted or refractory gold.

Diagnostic leach / mineralogy – To understand encapsulation and refractory behavior.

At Xinhai, we treat this stage very seriously. In many gold projects, our laboratory and process teams run a full program of gold ore testing before we recommend any flowsheet, precisely to avoid “designing by guess.”

03Common Mistakes When Trying to Recognize Gold Ore

Even experienced professionals can make mistakes in gold ore recognition. Here are the most frequent pitfalls to avoid:

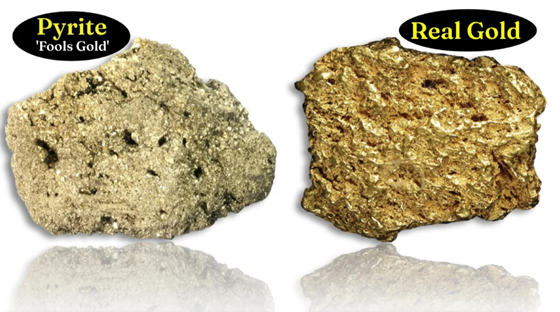

1. Confusing pyrite with gold: Pyrite (fool’s gold) is the most common impostor. Unlike gold, pyrite is brittle (breaks easily) and has a greenish-black streak. Always perform a streak test to distinguish the two.

2. Over-reliance on visual identification: Most gold in ore is microscopically fine-grained—never assume an ore is gold-free just because you can’t see gold flecks.

3. Ignoring gangue minerals: Gangue minerals (non-valuable minerals) can affect gold recoverability. For example, high clay content can complicate beneficiation, even if the gold grade is high.

4. Using unrepresentative samples: Collecting samples from only the surface or veiny outcrops can lead to inaccurate grade estimates. Always collect samples from multiple depths and locations.

04True Case Study in Gold Ore Identification

1. Liaoning Super-Large Gold Deposit, China

In 2025, a super-large gold deposit was confirmed in Liaoning Province, China. Drilling, core analysis, geophysical surveys, and 3D modeling identified approximately 1,444 tonnes of gold at an average grade of 0.56 g/t. Laboratory assays confirmed sulfide-hosted mineralization.

2. Copper–Gold Deposit, Indonesia

The Onto copper–gold deposit in Sumatra, Indonesia, was identified through diamond drilling, core assays, geophysics, fire assay, and XRF analysis. The porphyry-type system contains about 20 million ounces of gold (≈ 622 tonnes), ranking among the world’s top 20 deposits by 2025.

3. Fake Gold Ore Fraud Case, Kenya

In 2025, a fraud case in Kenya involved gold-plated or pyrite-based samples sold as gold ore. Laboratory testing confirmed no recoverable gold, highlighting common risks of visual misidentification in parts of Africa and Asia.

4. Ancient Gold Mining Site, Sukari Mountains, Egypt

Archaeological work in 2025 confirmed a 3,000-year-old gold mining camp in Egypt’s Sukari Mountains. Identification was based on ore residues, grinding tools, and metallurgical remains, verifying historical gold extraction

These cases show that gold ore identification depends on sampling, testing, and verification, not visual appearance.

05Xinhai: Your Trusted Partner for Gold Ore Evaluation and Project Execution

Recognising gold ore is just the first step—evaluating its value and translating it into a successful mining project requires comprehensive expertise. Xinhai has over 20 years of experience in global gold mining projects, offering EPC, EPC+M+O services that cover everything from ore testing and process design to equipment manufacturing and on-site operation.

If you’re struggling with gold ore recognition, need professional ore testing services, or want to discuss your gold mining project’s feasibility, feel free to contact us. We’ll arrange a one-on-one consultation with our senior mining engineers to help you make informed decisions.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE