Aluminum electrolysis slag contains significant amounts of high-value cryolite—but recovering it efficiently is far from simple. Using the Longkou Nanshan Aluminum project as a real-world case study, this article reveals the hidden challenges behind cryolite recycling and uncovers practical solutions for achieving stable, high-yield recovery.

Use the table of contents below to navigate through the guide:

01Project Initiation and Key Challenges

In aluminum electrolysis production, carbon residue is a long-standing by-product, with annual accumulations reaching hundreds of thousands of tons containing 20%–35% cryolite. Direct stockpiling not only occupies valuable plant space and poses potential risks of fluoride pollutibut also represents a waste of critical flux resources. Nanshan Aluminum’s Longkou plant faced this very challenge: piles of carbon residue occupied significant space, while the valuable cryolite within remained untapped. A resource utilization solution adaptable to existing plant conditions was urgently needed.

Against this backdrop, Nanshan Aluminum launched its carbon residue cryolite recovery project. The client’s requirements were clear: no new construction, no major structural modifications, establish a flotation production line with a design capacity of 3 t/h within the existing plant to achieve stable and efficient cryolite recovery. Xinhai Mining undertook the full scope of work—from process design and supply of core equipment to on-site installation guidance.

Now, let's see how this production line, from design to operation, achieved results that exceeded expectations within the old factory building.

02Overcome the Raw Material Problem

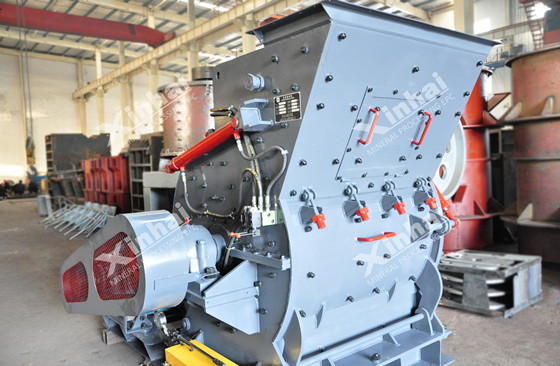

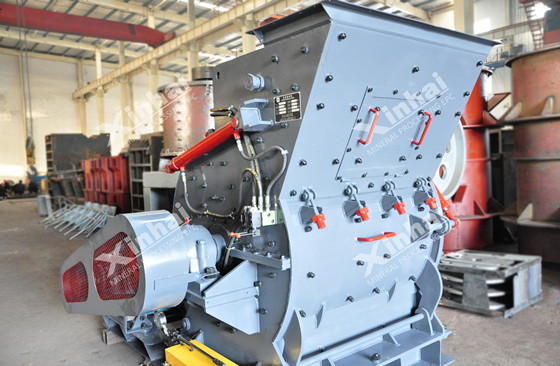

The first challenge came from the carbon residue itself. Initial inspections revealed large, hard lumps in the feedstock, which could clog downstream processes. “We need a crushing stage—and it has to be fine enough,” the team concluded. A hammer crusher was added for open-circuit crushing, transforming coarse material into uniform granules.

This was not simply an addition of equipment but a proactive adjustment based on material characteristics, ensuring downstream stability—a detail reflecting Xinhai’s experience accumulated from over a thousand projects.

☞Click to learn more about mineral processing projects

03Overcoming Plant Layout Constraints

The plant’s height difference posed another challenge—the production line needed to span two connected workshops, requiring material transfer across nearly 3 meters. Conventional conveyors would have taken up too much space and risked material blockage.

After repeated simulations using 3D modeling, engineers selected a bucket elevator as the core transfer device. Its excellent sealing and vertical efficiency addressed space limitations, reduced dust, and ensured stable operation—a factor the client frequently highlighted as a satisfaction point.

04Responding Swiftly to Unseen Risks: Aluminum Granule Separation

During the trial operation, we unexpectedly noted that some unseparated aluminum particles might still be present in the carbon slag—a detail the customer had not previously mentioned.

If overlooked, these could compromise cryolite purity and damage equipment. Overnight, the team devised a solution—installing custom screens at the grinding discharge point to separate and reclaim aluminum particles, adding unexpected value while protecting the system.

05Detailed Process Optimization

Attention to practical details continued throughout the project. Given that the filter press operates intermittently, the team added two buffer tanks upstream to provide temporary slurry storage and a consistent supply, thereby avoiding process interruptions. Belt feeders with real-time measurement were installed at silos to monitor ball mill throughput, making production scheduling transparent.

Foundations and operation platforms were built entirely with xinhai steel structure, eliminating the need for significant modifications to the old plant floor, saving construction time and reducing retrofit costs. These design choices reflect a deep understanding of mineral processing workflows.

06Sustainable Value: Turning Waste into Resource

The results spoke for themselves. When the first batch of cryolite concentrate with under 12% moisture was discharged, workers gathered in admiration. The fine white powder—a stark contrast to the former dark carbon residue—was quickly reintegrated into the electrolytic aluminum process.

To the client’s surprise, the designed processing capacity of 3 t/h was exceeded by 150 t/d during operation, far exceeding expectations.

Today, this retrofitted line plays a vital role in Nanshan Aluminum’s circular economy. Through crushing, grinding, and flotation, previously stockpiled carbon residue is transformed into high-value cryolite, saving millions in annual raw material costs while achieving harmless disposal of solid waste.

This success underscores a key principle: "a true partner not only solves stated problems but anticipates hidden risks."

At the heart of mining engineering lies the ability to resolve production challenges with professionalism. With over 30 years in mineral processing, Xinhai’s strength isn’t just technical parameters—it’s the confidence to solve problems. From spatial planning and rapid troubleshooting to precise process design and capacity assurance, every step is grounded in practicality and partnership.

The Nanshan Aluminum project proves that with sound methods and stable processes, even discarded materials can regain value.

Ready to Optimize Your Project?

If you’re exploring tailored solutions for your mining or solid waste operations, reach out to discuss the most suitable processes and pathways together.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE