As a key component of electric vehicles, lithium batteries have seen

explosive demand growth in recent years. This surge has driven the rapid

expansion of the lithium resource development industry. However, construction

lithium processing plants often presents several challenges, including unstable

processes, cost overruns, difficulties in multi-party coordination, and low

operational efficiency. The EPC+M+O model effectively addresses these issues. It

is a closed-loop management approach that spans from mineral processing tests to

plant operation, reducing construction delays and resource waste through

integrated project delivery. This article outlines the process and advantages of

using the EPC+M+O model to establish a lithium processing plant.

Use the table of contents below to navigate through the guide:

01Lithium processing plant construction process

1. Mineral dressing test

The mineral dressing test requires 50–200 kg of representative

ore samples. First, the ore properties are analyzed, including chemical

composition, mineralogical characteristics, and grain size distribution (mineral

liberation). Next, the physical properties of the ore are tested, including

hardness index, specific gravity, magnetic susceptibility, and electrical

conductivity differences.

Exploratory tests are conducted to verify technical feasibility, typically

including crushing and grinding tests, as well as pre-concentration and

rejection tests. Crushing and grinding tests help determine the appropriate

crushing circuit and grinding fineness for lithium ore. Pre-concentration and

rejection tests may involve dense medium separation (DMS) or sensor-based ore

sorting techniques such as X-ray or optical sorting.

Flotation condition tests are performed to optimize the type and dosage of

collectors, the selection of depressants, and pH adjustment. Dewatering and

tailings treatment tests are used to determine the appropriate models for

thickeners and dewatering equipment.

2. Process design

The process flow is designed based on the results of the lithium ore

beneficiation test. The lithium ore processing flow includes the following

stages:

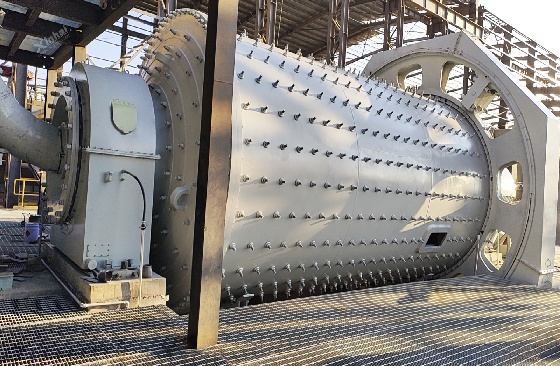

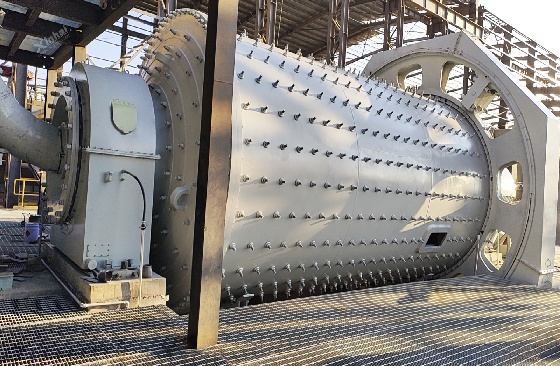

Ore Pretreatment: The lithium ore is first crushed and

screened to a particle size below 15 mm. Pre-concentration is conducted via

dense medium separation (DMS). The ore is then subjected to grinding and

classification using a ball mill and spiral classifier, with the target particle

size controlled to -0.074 mm, accounting for 75%–90% of the material.

Lithium Extraction Process: Whether dealing with spodumene

or lepidolite, lithium extraction typically adopts a froth flotation

process.

For spodumene, the flotation process usually follows the sequence: roughing →

3–5 stages of cleaning → scavenging.

For lepidolite, the typical flotation flow is: pre-desliming → roughing →

reverse flotation.

Lithium Compound Synthesis: Sodium carbonate (Na₂CO₃) is

added to the lithium-bearing solution, and lithium carbonate is produced through

a precipitation reaction followed by centrifugal separation and drying. Calcium

hydroxide (Ca(OH)₂) is used to synthesize lithium hydroxide via a causticization

reaction, followed by filtration and evaporation crystallization.

Tailings Treatment: The tailings produced after flotation

occupy a large storage area. To reduce moisture content and environmental

impact, deep cone thickeners, dewatering screens, and related

equipment are used for tailings dewatering and dry

stacking.

3. Equipment manufacturing, installation and

commissioning

Equipment Manufacturing:

Mineral processing equipment is custom-designed based on the specific process

requirements and optimized using data from beneficiation test results. The core

equipment is independently developed by Xinhai to ensure high performance and

adaptability.

Equipment Installation:

During installation, a modular design approach is adopted to enable rapid

lifting and assembly. Millimeter-level precision calibration is performed using

laser levels and total stations. Strict quality control is implemented for

pipeline welding and electrical system safety. At the same time, the DCS

intelligent control system and sensor network are deployed. Upon completion of

installation, integrated material flow debugging is conducted to ensure all

system indicators meet the design specifications.

4. Plant Operation

After the lithium processing plant was commissioned, Xinhai Mining continued

to manage its operations, including operator training and equipment parameter

optimization. An intelligent data platform was utilized to dynamically adjust

reagent dosing, ensuring that the lithium recovery rate met project

expectations. Additionally, Xinhai provided environmental compliance support to

help ensure that wastewater and solid waste discharge met local environmental

regulations.

02Advantages of EPC+M+O model in construction lithium processing plants

1. Fixed-Price Contract

Through innovative planning, Xinhai tailors design solutions for each lithium

mining project and determines contract value using scientific and accurate

accounting methods, effectively avoiding budget overruns. A detailed

construction schedule and strict assessment system are implemented to prevent

repeated design changes and additional costs.

2. Guaranteed Compliance and Smooth Production

Xinhai provides customers with full-process management services and

integrated solutions, emphasizing the coordination and capacity matching of main

and auxiliary equipment throughout the production line. Our strong capabilities

in on-site process inspection, equipment diagnostics, and concentrator

supervision ensure compliance with design standards and stable production.

3. Avoiding Construction Delays

The EPC+M+O model offers a one-stop, full-cycle service that eliminates the

challenges of multi-party coordination. Xinhai considers equipment installation

and commissioning needs early in the design phase, ensuring seamless project

integration and on-time delivery, thereby avoiding construction delays.

03EPC+M+O Lithium Processing Plant Project Case

In 2022, Xinhai Mining undertook a 2 million t/a lithium project in

Zimbabwe, delivering tailored mining industry chain services under the

EPC+M+O model—including design, equipment manufacturing and procurement, as well

as commissioning and delivery.

The beneficiation process designed by Xinhai includes:

Dense medium separation for petalite recovery → gravity separation for

tantalum and niobium → flotation for mica → flotation for spodumene.

The project entered trial operation in July 2023, taking just one year from

construction start to commissioning. Throughout the project, Xinhai ensured

steady progress and successful advancement into the trial production stage. In

the operational phase, Xinhai continues to showcase its strengths in mine

operation and management, further optimizing project investment, cost, and

returns.

In early 2025, Xinhai Mining received a thank-you letter from the Zimbabwe

client, praising the advanced beneficiation design, reliable equipment quality,

and professional operation team.

Conclusion

This article outlines the complete process of building a lithium processing

plant, highlights the advantages of the EPC+M+O model, and showcases Xinhai

Mining's project execution capabilities through a successful case in

Zimbabwe.

If you have any lithium ore processing needs, feel free to contact us!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE

.jpg)