Gold is not only a globally recognized form of hard currency but also a key

focus in mining exploration and extraction. Among the various types of gold

deposits, Placer Gold(alluvial gold) and Lode Gold are the most common,

representing secondary enrichment and primary accumulation in geological

evolution, respectively.

Placer gold is typically found in riverbeds or ancient alluvial deposits and

is relatively easy to extract using simple methods. In contrast, lode gold is

embedded in hard rock formations and requires more complex techniques such as

drilling and blasting.

So, what is the difference between placer gold and lode gold? And how can

mining operations select the right processing method and equipment based on

orebody characteristics?

In this article, we’ll walk you through the fundamental differences between

placer gold and lode gold—covering their geological features, mining processes,

and economic implications. Whether you're evaluating a new gold project or

exploring mineral processing strategies, this guide will help you better assess

project feasibility and make more informed technical and investment decisions.

If you're involved in mining planning or simply interested in the world of gold

extraction, keep reading!

Use the table of contents below to navigate through the guide:

01Placer Gold Vs Lode Gold: Definition and Geological Characteristics

1. What is the meaning of placer gold?

Placer gold refers to secondary gold deposits that have been re-deposited on

or near the Earth’s surface after weathering, transportation by water, and

natural sorting from primary gold sources.

Typical environments: River gravels, alluvial fans, ancient

streambeds.

Morphological characteristics: Mostly flat or rounded

particles, typically ranging from 0.1 to 5 mm in size.

Commonly associated minerals: Quartz, limonite.

Purity: Generally contains more impurities, with gold (Au)

content usually less than 10%.

2.What is lode gold?

Lode gold refers to primary gold deposits found in bedrock fractures, quartz

veins, or hydrothermal alteration zones. These deposits form deep underground

through primary geological processes.

Typical environments: Bedrock fissures, quartz veins,

sulfide-rich ore bodies.

Morphological characteristics: Wide variation in particle

size—from microscopic gold to large nuggets.

Commonly associated minerals: Pyrite, silver, and tellurium;

often form polymetallic ores such as Au-Ag-Te.

Purity: Relatively high, with Au content often exceeding

90%.

3. Placer Gold Vs Lode Gold: Comparison of Geological

Features

| Characteristic | Placer Gold | Lode Gold |

|---|

| Occurrence | Found in loose surface deposits like gravel beds | Found in hard bedrock such as quartz or sulfide veins |

| Gold Form | Free gold in the form of grains, flakes, or nuggets | Often microscopic or locked within sulfide minerals |

| Mobility | Free gold in the form of grains, flakes, or nuggets | Fixed—embedded in rock, requires crushing to extract |

02Placer Gold Vs Lode Gold: Comparison of Mining and Gold Extraction

Processes

The physical form of gold plays a crucial role in determining the appropriate

extraction method. In general, placer gold is easier to extract due to its loose

and unconsolidated nature. In contrast, lode gold extraction requires more

complex crushing, grinding, and metallurgical treatment.

1. Placer Gold: Mining And Extraction

(1)How is placer mining done

Placer gold is typically found in riverbeds, alluvial fans, or ancient river

channels, where it accumulates due to gravity. Extraction relies on the density

difference between gold and surrounding materials. Common mining methods

include:

Manual panning: Suitable for small-scale or artisanal

mining; involves using pans to separate gold particles in water.

Shallow open-pit mining: Uses excavators or bulldozers to

strip away gravel layers; ideal for medium- to large-scale operations.

Hydraulic mining: Employs high-pressure water jets to

dislodge gold-bearing sediments; highly efficient but potentially damaging to

the environment if not properly managed.

(2)Gold Extraction Techniques

Placer gold does not require crushing or grinding, making its beneficiation

process relatively straightforward and cost-effective. Key techniques

include:

Gravity separation (e.g., spiral chutes, jigging machine,

concentrating table): Exploits the high density of gold to separate it from

lighter minerals. Recovery rates can exceed 90%.

Amalgamation with mercury: Historically used but now largely

phased out due to environmental and health concerns.

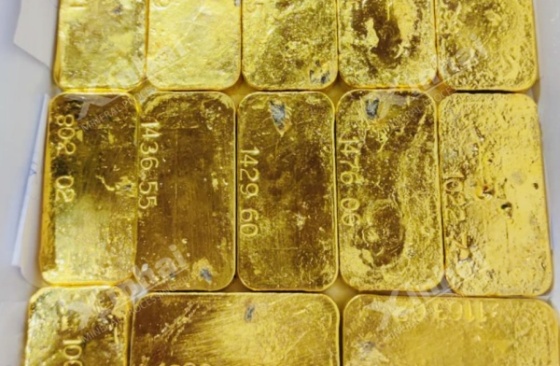

Smelting: Gold concentrates from gravity separation are

often smelted directly into bullion without additional chemical processing.

2. Lode Gold: Mining And Gold Extraction

(1)what is lode mining

Lode gold occurs within hard rock formations and requires systematic mining

approaches. Common methods include:

Underground mining: Involves vertical shafts, inclined

shafts, or tunnel systems; suitable for deep and narrow ore veins.

Open-pit (bench) mining: Applied to shallow and wide ore

bodies using step-like benches to access the ore.

Drilling and blasting: Explosives are used to fragment the

rock, followed by excavation and haulage using loaders, trucks, or conveyor

systems.

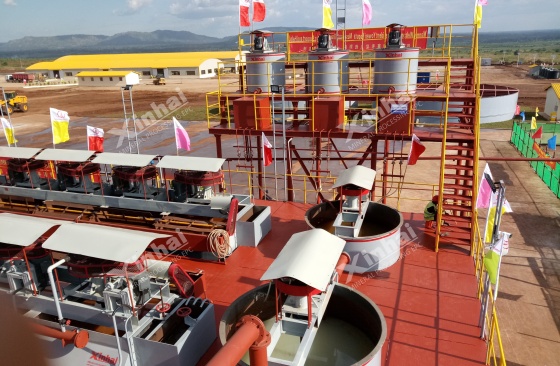

(2)Beneficiation and Gold Extraction

Lode gold ores often contain fine-grained gold interlocked with sulfides or

silicates, requiring multi-stage processing to ensure efficient recovery.

Typical procedures include:

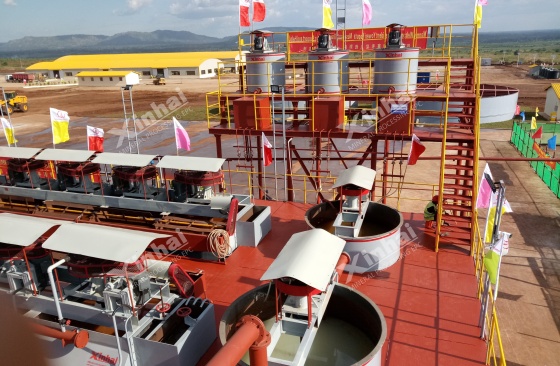

Crushing and grinding: Jaw crushers, cone crushers, and ball

mills are used to liberate gold from the host rock, preparing it for downstream

processing.

Flotation: Ideal for gold-bearing sulfide ores; uses

flotation cells and high-efficiency agitation tanks to produce gold-rich

concentrates while removing gangue minerals.

Roasting or pressure oxidation: Employed as pre-treatment

for refractory ores containing arsenic, sulfur, or carbon, improving subsequent

cyanide leaching efficiency.

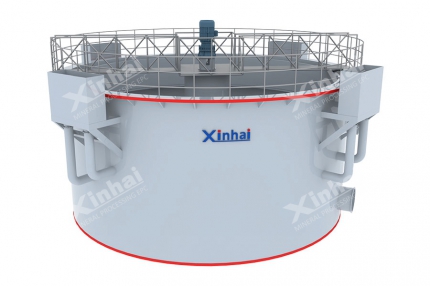

Cyanide leaching: The most widely used extraction method.

Leaching tanks—such as double-impeller high-efficiency agitation tanks—combined

with CIP or CIL systems are used to dissolve and recover gold from ore with high

recovery rates.

03Economic Benefit Analysis

Placer gold and lode gold projects differ significantly in terms of

investment scale, operational complexity, and return cycles.

Alluvial gold projects typically have a low entry threshold. With relatively

simple equipment—such as shaking tables or panning discs—basic gold recovery can

be achieved quickly. These projects are well-suited for rapid deployment and

short-term returns, often allowing investors to recover capital within a few

months to two years. However, due to the scattered nature of gold particles and

limited ore reserves, recovery rates can be modest. Operations are also

vulnerable to seasonal factors; for example, heavy rains can significantly

hinder mining activities.

Lode gold projects, on the other hand, are capital-intensive and involve a

full suite of processes—drilling, blasting, hauling, and beneficiation. While

initial investment can reach tens of millions of dollars, the payoff is usually

higher over the long term thanks to higher resource concentration and gold

recovery rates. However, such projects also require longer construction and

ramp-up periods.

Conclusion

Whether working with placer gold or lode gold, both offer significant

development potential. The key to success lies in aligning mining and processing

strategies with the specific characteristics of the ore body to maximize

resource utilization and investment returns.

For instance, gravity separation equipment is especially effective in

alluvial gold recovery. In lode gold operations, advanced technologies—such as

double-impeller leaching agitation tanks and CIP systems—can greatly enhance

gold recovery efficiency.

If you're planning a gold project or exploring equipment options tailored to

your ore type, we invite you to follow Xinhai China for more professional

insights, technical references, and real-world case studies.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE