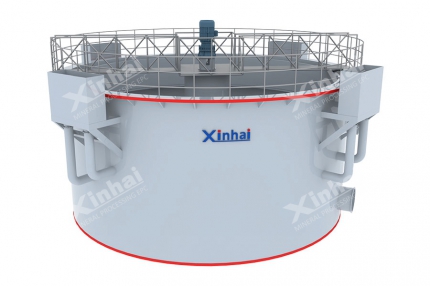

A double-impeller leaching agitator tank is an efficient mixing device

designed for cyanide leaching in the extraction of precious metals like gold and

silver. It features upper and lower impellers and is typically equipped with an

axial flow guide, which enhances slurry mixing, improves oxygen utilization, and

accelerates gold leaching—making it essential in modern CIP and CIL

processes.

Compared with traditional agitators, Xinhai’s self-developed double-impeller

leaching tank handles slurries up to -200 mesh and under 45% concentration. It

combines leaching and carbon adsorption and is also suitable for stirring and

leaching in metallurgy, chemicals, and light industries.

In this article, we will explore the core structure and working principle of

Xinhai’s double-impeller agitator tank, analyze its technical advantages in gold

cyanidation, and summarize the types of ores and process conditions it is best

suited for. Read on to gain a comprehensive understanding of this equipment and

discover how it can serve as a professional reference for your project planning

and equipment selection.

Use the table of contents below to navigate through the guide:

01The Core Structure and Working Principle of the Double-Impeller Leaching

Agitation Tank

The double-impeller leaching tank typically consists of the following

components: tank body, agitation device, baffle plate, transmission device,

shaft sealing system, and other supporting parts.

Tank Body: Made of stainless steel or lined with

corrosion-resistant materials, the tank is cylindrical in shape with either a

conical or flat bottom. Baffles are installed along the inner wall to enhance

the mixing effect.

Agitation Device: It features a dual-impeller system, with

impellers—typically of paddle or turbine design—working in tandem to achieve

efficient material mixing. The impellers are centrally mounted within the tank

and driven by a transmission system.

Baffle Plate: Typically made from stainless steel (e.g.,

304, 316L) or non-metallic materials (e.g., PVC, PTFE), the baffle disrupts the

vortex generated by the impellers. This improves mixing uniformity, reduces

energy loss caused by vortex formation, and helps prevent solid particle

sedimentation.

Transmission Device: Comprising a motor, reducer, and

coupling, this system transmits power and regulates the rotation speed of the

impellers.

Shaft Sealing Device: Uses either packing seals or

mechanical seals to prevent material leakage during operation.

02Technical Advantages of the Double-Impeller Leaching Agitation Tank

– Using Gold Ore Cyanide Leaching as an Example

The cyanide leaching tank plays a crucial role in the gold extraction

process. It provides a stable and controllable reaction environment that

facilitates full contact and reaction between the leaching agent and the ore.

This significantly improves both the leaching efficiency and gold recovery rate,

while also ensuring the economic viability and sustainability of the overall

beneficiation operation.

Below are 4 key technical advantages of the double-impeller agitating

leaching tank in the cyanide leaching process of gold ore:

1. Enhanced Cyanide Leaching And Carbon Adsorption Rates

The dual-impeller design increases slurry circulation paths and ensures

uniform distribution of slurry concentration and fineness. This enables greater

exposure of gold particles to the reaction medium, thereby improving the cyanide

leaching rate and carbon adsorption efficiency.

2. High Oxygen Utilization

Oxygen is introduced into the gold leaching tanks through a hollow shaft at

the bottom. This design extends oxygen residence time in the slurry, ensures

even distribution, and creates fine bubbles, all of which enhance oxygen

utilization during the leaching process.

3. Energy Efficiency And Reduced Wear

The high efficiency agitation tank features a compact structure for easy

maintenance.

The impellers are lined with wear-resistant rubber, extending service

life.

Large-diameter impellers operate at low speeds, reducing power consumption

and minimizing carbon wear—making the system more energy-efficient than

traditional single-impeller designs.

4. Prevention Of Ore Settling And Dead Zones

The wide agitation range ensures more uniform slurry distribution,

effectively preventing ore particles from settling at the bottom or accumulating

in dead zones.

This design is especially well-suited for handling difficult-to-leach ores

such as clay-rich ores and those with high mud content.

03Applicable Ore Types and Processes for the Leaching Agitation Tank

The Xinhai double-impeller leaching agitation tank is widely used across

various gold ore types due to its excellent mixing performance, high leaching

efficiency, and operational sustainability. It is particularly effective in

handling the following 5 types of complex ores:

1. Oxidized gold ores with high clay content

2. Fine-grained disseminated gold ores

3. Sulfide-encapsulated or arsenic-bearing gold ores

4. Complex ores with heavy metal impurities

5. Ultra-low-grade gold ores

In addition to its broad ore adaptability, the double-impeller leaching

agitation tank is also applicable in a variety of process flows, including:

1. CIL (Carbon-in-Leach) process

2. CIP (Carbon-in-Pulp) process

3. Combined processes involving oxidation pretreatment followed by

cyanidation

4. Pre-treatment leaching stages prior to heap leaching

04Specific Case Studies

1. Sudan 300t/d Gold Ore Beneficiation Project

Project Background:

This project processes gold tailings with fine particle size and a gold grade

of 4.7 g/t. Since the raw ore is already finely ground, no crushing is

required.

Process Flow:

The adopted process includes pre-screening, one-stage closed-circuit grinding

and classification, thickening, cyanide leaching, desorption electrolysis,

smelting, and tailings pressure filtration and dewatering.

Equipment Application:

During the cyanide leaching stage, Xinhai's double-impeller high-efficiency

leaching agitation tank is employed for both leaching and carbon adsorption. The

system also includes Roots blower aeration and sodium cyanide (NaCN) dosing to

ensure thorough mixing and reaction between the slurry, reagents, and air.

Project Results:

The gold leaching rate reached 95.7%, the carbon adsorption rate was 99%, and

the overall gold recovery rate was as high as 91.93%.

2. Iran 300t/d Gold Ore Beneficiation Project

Project Background:

The ores treated in this project include both oxidized and sulfide gold ores,

with average gold grades of 2.5 g/t and 3.39 g/t, respectively.

Equipment Application:

Xinhai designed a combined process of alkali pretreatment and cyanide

leaching. The double-impeller leaching agitation tank is used for both the

pretreatment and leaching stages, ensuring uniform mixing and improved reaction

efficiency.

Project Achievements:

With the optimized agitation system, the leaching time for oxidized ore was

32 hours and for sulfide ore 24 hours. The final gold ingot purity exceeded

99.5%.

Summary

In conclusion, the double-impeller leaching agitation tank offers outstanding

process efficiency and economic benefits in the gold cyanidation process. By

enhancing gold recovery, lowering cyanide consumption, and promoting sustainable

production, it has become a preferred choice in modern gold beneficiation

plants.

If you would like to learn more about this equipment or receive a customized

solution tailored to your specific mineral processing needs, please feel free to

contact XinHai group. Our team is ready to provide you with professional

technical support and dedicated service.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE