Copper extraction is the process of separating and purifying copper from the

gangue minerals in copper ore. Copper ore can be classified into sulfide copper

ore and oxide copper ore based on the degree of oxidation and ore grade.

Depending on the type of copper ore, two different extraction methods can be

employed: pyrometallurgy and hydrometallurgy.

This article provides a step-by-step guide to copper extraction using both of

these methods.

Use the table of contents below to navigate through the guide:

01Copper Sulfide Ore Extraction Step-by-Step Guide

1. Crushing and Grinding

Depending on the required reduction ratio, the crushing stage can be

configured in two or three stages. A jaw crusher is used for primary crushing to

reduce the raw ore to 100–200 mm. A cone crusher or hammer crusher is then used

for secondary crushing.

The crushed copper ore is screened, and the undersized material is sent to a

ball mill for grinding, while oversized material is returned to the secondary or

tertiary crushing stage. The ball mill typically grinds the ore to a discharge

particle size of 0.074 mm (200 mesh) to ensure full dissociation of the copper

minerals.

2. Flotation Enrichment

Flotation reagents: For the flotation of copper sulfide ores, xanthate is

typically used as a collector, pine oil as a frother, and lime as a pH regulator

to adjust the slurry to a pH of 9–11. An efficient agitation tank is used to

fully mix the ore, reagents, and air, facilitating the subsequent froth

flotation process.

Flotation process: A roughing–cleaning–scavenging flotation process is

adopted. During roughing, a rough concentrate with a copper grade of 5–15% is

obtained. After multiple cleaning stages, a final copper concentrate with a

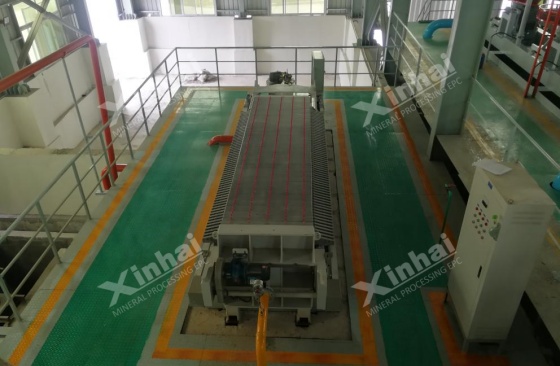

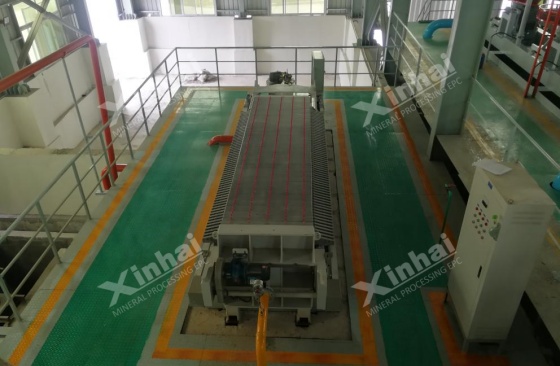

grade of 20–30% is produced. The flotation tailings are thickened using a

high-rate thickener and then either stored or used for backfilling.

3. Smelting

Dry copper concentrate and oxygen-enriched air are injected into the reaction

tower for oxidation smelting, producing matte copper. The matte undergoes two

stages of converting (blowing) to yield blister copper.

4. Refining

An anode furnace is used for fire refining to cast anode plates. These anode

plates, together with stainless steel cathode plates, are immersed in a copper

sulfate electrolyte and undergo electrorefining in electrolytic cells. This

process yields cathode copper and anode slime containing Au, Ag, and Pt, which

are further refined for precious metal recovery.

02Copper Oxide Ore Extraction Step-by-Step Guide

Copper oxide ores and refractory composite ores are usually extracted using

hydrometallurgical methods, which typically involve the following steps:

1. Heap Leaching / Tank Leaching

Low-grade ore is pretreated by heap leaching, during which dilute sulfuric

acid is sprayed over the ore heap. The heap leaching cycle is relatively long,

typically lasting 30 to 180 days. High-grade copper oxide ore is crushed to less

than 5 mm and then leached with sulfuric acid in a stirred tank at a reaction

temperature of 50–80°C for 4 to 12 hours.

2. Leachate Enrichment

The leachate obtained from heap or tank leaching is separated using a

thickener or filter to produce a copper-containing solution.

3. Solvent Extraction (SX)

The leachate is first mixed with an organic phase and then stripped with

concentrated sulfuric acid to obtain a copper-rich electrolyte.

4. Electrowinning (EW)

In the electrolytic cell, lead-calcium alloy anodes and stainless steel

cathodes are immersed in the copper-rich electrolyte.

03Comparison of Two Copper Extraction Methods

The product purity achieved by both the sulfide copper ore extraction method

and the oxide copper ore extraction method can reach 99.99%. Sulfide ores with a

copper grade greater than 0.5% are typically treated by pyrometallurgy, while

oxide ores or low-grade ores with a copper grade less than 0.5% are processed

using hydrometallurgy.

Pyrometallurgy involves relatively high investment costs and energy

consumption, and the SO₂ released must be treated before discharge. In contrast,

hydrometallurgy has lower costs and energy consumption, generates no gas

emissions, and produces wastewater that is easier to manage.

The above content introduces the extraction steps for the two types of copper

ores. In actual production, the extraction method should be determined based on

the results of ore dressing tests to ensure optimal utilization of mineral

resources and avoid waste. If you have any copper extraction needs, please feel

free to contact us.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE